How do I detect leaks from a distance? How do I assess the quality of surface cleaning processes? How do I measure the malleability of dough? How do I monitor patients in care beds? Every company faces its own process issues. And human operators can only do so much. So, let’s make tech work. With sensing solutions and automated quality assessment, you can boost both productivity and quality.

Contact us

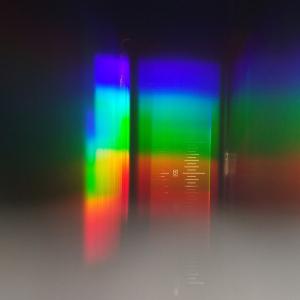

Sensing solutions and automated quality assessment

Qualitative data, the key to smarter decisions

Experienced operators usually see, hear or feel if a process is running as planned. But it’s becoming increasingly difficult to find qualified operators. On top of that, people inevitably cause variance with their specific sensitivity. This limits the scalability and further improvement of the process. The good news: sensing can offer a way out by making your processes smarter.

Inspiring articles

Wonder what a sensing and automated quality assessment could mean for you?

Gert Heirman, Program Manager Mechatronics, is ready to find the answer together.

Get in touch