Products are expected to be smaller and smarter today, while the development and production should be faster and costs must be kept low. Not even the sector of medical diagnostics can escape this trend and is required to offer fast, inexpensive diagnostic tests performed at the patient’s bedside. If you want to start this kind of development, you can count on the support of Sirris and Medvia.

Point-of-care tests (PoCT) can be used to diagnose certain physical conditions or diseases. This is possible through detection and quantification of different types of analytes, such as metabolites (as in pregnancy tests), blood chemicals (as in blood sugar tests)and other biomarkers, such as proteins (e.g. in antigen-antibody immunoassays, like a Covid self-test detects the virus), but also through the counting and classification of cells or through the analysis of DNA (as in a Covid PCR test).

Miniaturising the diagnostic testing process requires less reagents, speeds up the process (such as heating or cooling) and makes it accurately manageable. As a result, diagnostic tests can be performed cheaper, faster and at the patient’s side.

How is this microprocess implemented?

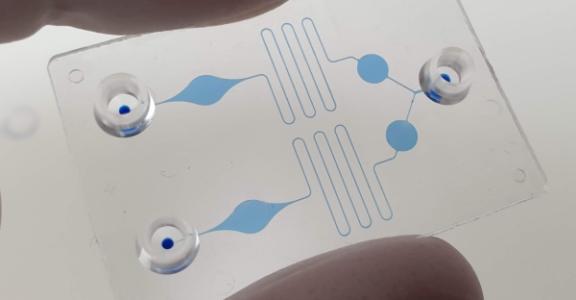

- A miniature lab is created on an injection-moulded microfluidic chip.

- This microfluidic chip can be produced in large numbers cheaply and quickly.

- All sample preparation steps can be integrated on the chip. During the execution of the test, only the test sample needs to be added, and this can be done by a non-specialist.

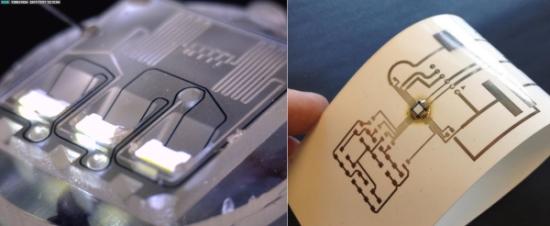

- A reusable conditioning and reading device interacts with the testing process on the chip and contains all the smart technology to prepare the sample and measure the test result.

Does your company operate in the medtech or biotech sector, do you work on diagnostics and want to focus on point-of-care diagnostic tests? Do you work in the injection moulding industry and would you like to focus on microfabrication? Or are you a product manufacturer interested in sensor technology applied in diagnostic tests? Then we can help you develop your case! (see e.g Microchip for rapid antibiotic-resistant bacteria testing | Sirris and An instantaneous blood test at the patient's bedside | Sirris).

Knowledge and services available

In the COOCK project 'Medical diagnostics goes micro and smart' we are integrating an extensive set of knowledge domains that Sirris has developed in recent years in the field of microtechnologies, smart automation technologies and development methods.

What is the specific knowledge and services that your business needs?

- The translation of the diagnostic test process into functions on the microfluidic chip and in the conditioning device.

- Design of the microfluidic features that realise the functions in the chip.

- Realisation of initial proofs of concept, functional prototypes and pre-series using micromachining (milling, EDM), micro 3D printing, injection moulding, ultrasonic replication, Soft-UV nanoimprint lithography, surface functionalisation, various sealing and joining techniques.

- Integration of sensors in microfluidic chips or your reading device.

Based on your specific case, we will give you an introduction to this knowledge and techniques, with the ultimate aim of integrating it into your company so that you can carry out such projects independently.

Interested? Get in touch with us and submit your case!