Do none of the commercially available materials have the exact properties you are looking for? Then it’s time to design advanced materials that do. Materials innovation in additive manufacturing (AM) requires a thorough understanding of the process and its parameters, on top of the know-how to build a proof of concept. And that is exactly the service we offer.

New materials for additive manufacturing

Optimise your offering

Examples abound of possible material improvements:

- Aluminium alloys for aeronautics that are not yet processable with AM technologies

- Polymers with adequate elongation, but with a suboptimal resistance to hydrolysis

- Bio-compatible polymers with controlled resorption times in the medical industry

Sirris helps you achieve such improvements through AM process and materials development. Whether the material feedstock is a powder, filament or a viscous liquid, our experts know what to do.

Assistance for various AM technologies and quantities

Even if your application requires only a small quantity, we help you develop new materials..

Our AM technologies:

- Electron Beam Powder Bed Fusion (E-BPF)

- Laser Powder Bed Fusion (L-PBF)

- Selective Laser Sintering (SLS)

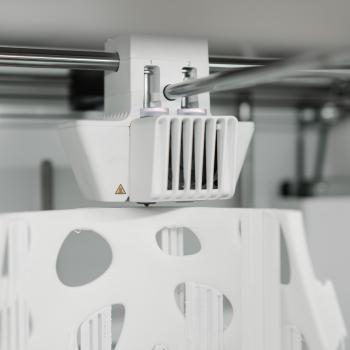

- Fused Deposition Modelling (FDM)

- Digital Light Processing (DLP)

- Masked Stereolithography Apparatus (MLSA)

- Syringe Robot Casting (SRC)

The majority of Sirris’s additive manufacturing equipment can be fully parametrised, and multiple slicer software packages are available.

A 7-fold service: pick and choose

Feedstock

Our experts make a difference in optimising your feedstock.

Filament

WIth the mini-extruder we transform your powder or pellet polymers (charged or not) into a filament with a specific diameter (max. 4 mm).

Material enhancement

We enhance the properties and/or improve the “printability” of the material through better formulation.

Testing

Tests can be performed such as powder characterisation, thermal analysis and mechanical behaviour, on feedstock or end-product.

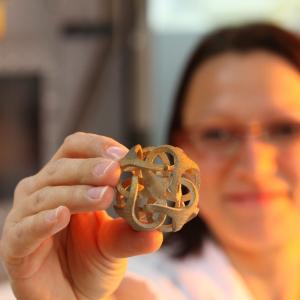

Proof of concept

Testresults can be assesed in the AM machine, by building a proof of concept to validate the material for your application.

Quality control

We perform quality control, such as dimensional accuracy, mechanical strength, material quality and material aging.

Nabewerking

A post-treatment is carried out, such as polishing/tribo-finition, thermal treatment, impregnation, coating and CNC.

Inspiring articles

Interested in new materials for additive manufacturing?

Guido Heunen and his colleagues from our additive manufacturing team will show you the way!