Today many market segments are moving towards automobile requirements: making the reduction of production costs sustainable, and achieving quality/delivery goals close to perfection while proposing personalised products to customers. Taking these new expectations into account requires a breakthrough. Quick Response Manufacturing (QRM) is providing the answer.

One principle of QRM is to organise the company into a network of cells. Each cell is created so that all the jobs arriving in this cell undergo there all the successive operations needed before leaving it without continual toing and froing with other cells. This means grouping resources close to one another in an area clearly identified as belonging to the cell.

Traditionally, the dimensional control of parts is carried out in a centralised space managed by the 'quality control' department. To produce a fully self-contained cell, make significant time savings and improve control reliability, it is best to integrate the dimensional control of parts right in the production process. This process allows operators to better understand customer requirements and makes it possible to continuously adjust production parameters to take account of the machine environment (tool wear, temperature fluctuation).

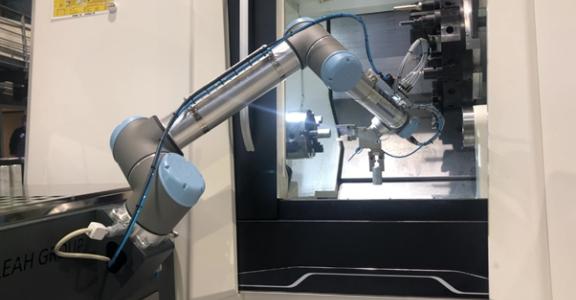

To illustrate this process concretely, a workshop on the robotisation of a machining unit equipped with a metrology unit was held on 30 March 2022 at Technifutur in Liège as part of the Interreg Euregio QRM 4.0 project. A cell composed of one machining centre, a UR robot and a metrology unit were demonstrated.