New trend in operator support offers numerous possibilities

Digital work instruction systems are still on the rise and, in addition to various digital tools, now also integrate AI so that operators can quickly gain access to the correct relevant knowledge. We tested the options and have set them out for you.

With digitisation, the rise of AI is also continuing in industry. In the field of digital work instructions, techniques such as the use of smart glasses and projected instructions have already been introduced. A step further is now possible with the introduction of chatbots such as ChatGPT into the workplace.

At the end of 2022, the use and potential of AI gained momentum with the arrival of ChatGPT (and the OpenAI API) - a chatbot with artificial intelligence developed by OpenAI. This chatbot also has potential for use in an industrial (manufacturing) environment.

Anyone who wants to create or improve digital work instructions with the help of AI must understand both. Moreover, the integration of AI is not so simple. The suppliers of digital work instructions do their best to make the use of their product a smooth experience for the users - the process engineers who draw up the work instructions and thereby the operators.

The possible advantages of using AI in preparing digital work instructions include making things easier and faster, with less effort, less stress, fewer errors, greater consistency, etc.

AI and digital work instructions

Text-based instruction support

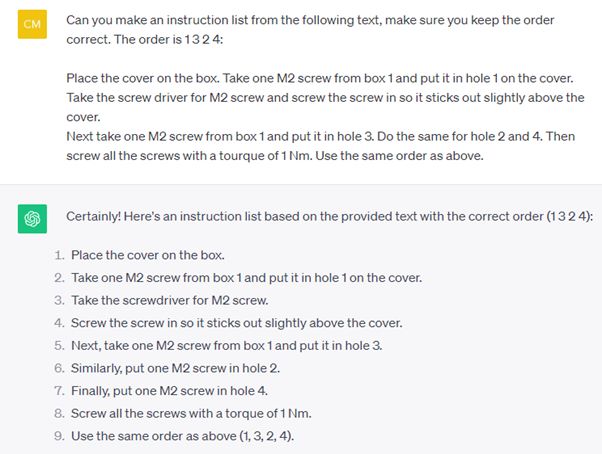

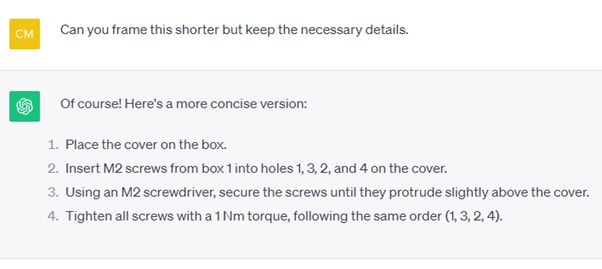

We put it to the test and asked ChatGPT via prompts to turn a continuous text into a step-by-step instruction, paying attention to the correct order:

We then asked it to shorten the result, keeping the essential details:

Automatic improvement of instructions

In addition, automatic improvement of the instructions is also possible via the OpenAI API or you can use integrated AI copilots:

- Digital work instructions creators allow you to generate rough, non-standardised work instructions

- If you send your input to OpenAI (via the API), you will receive shorter instructions in more direct language, according to the company-specific standard (you must include this with your queries).

An alternative is Microsoft 356 Copilot for use in Word, Excel, PowerPoint, etc.

Extensive possibilities

In addition to formulating or optimising work instructions, tools such as ChatGPT can also translate them. With automatic translation of instructions (content), they were traditionally translated via the API by Google, Microsoft, etc., but this can now be done directly via the API by ChatGPT.

Traditionally, translation tables were used to translate the application interface, but this can now also be done live via the ChatGPT API.

Instructions can be entered or spoken-in via ChatGPT or the API of platform plugins. Voice instructions are created live and then appear in the application.

You can ask ChatGTP for help in drawing up instructions or troubleshooting via text and images. This might be something like step-by-step instructions for repairing a bicycle using photos of the bicycle, details, tools, etc.

Videos can also be embedded in the work instructions and automatically translated into a language of your choice. We did the test and made a video about putting together a weather station and had it automatically translated into Ukrainian. This can be done via AI tool HeyGen, which will make it seem as if you are speaking a language fluently that you don’t actually know. This is done by recording a video message via the program, which is then translated into a language of your choice. In this way, a complete video or fragment can be integrated into digital work instructions.

On operator side

When the process engineer uses AI for preparing work instructions, the operators can also reap the benefits.

For example, the operator can enter the reason for a machine stoppage, which is done in a free text field. AI then converts the error into a table with fixed and known stoppage. This means that the operator does not have to look up the right cause from a list of possibilities.

Other options include operator troubleshooting (via document querying). If you upload handbooks and service manuals of certain devices to a ChatGPT-like system, it also becomes possible to find the causes of a problem using the correct prompts via a chat interface, as well as the actions required to solve the problem itself.

End-of-line quality inspection is typically done by a human operator and is generally considered too difficult to automate. It usually consists of ticking off set items from a checklist. This step can also be assisted by AI. For example, a checklist can be completed step by step with a visual system that knows what the specific steps should look like according to a pre-assembled library. That library must of course first be taught what is good, what is bad and what is acceptable, etc.

Analysis and insight acquisition

Analysis can be performed and insights gained by using data from the digital work instruction system: For example, the system can assign an efficiency score to operators (speed, quality level, skills, etc.), which can be taken into account when planning and assigning new assembly tasks.

Digital operator support in your company too?

Are you interested in how the integration of digital work instructions can make your production operators (even) better? In recent years, Sirris has expanded its expertise and services in this domain. By working together with you, we can look at your situation and find the right solutions and tools for your challenge. We help you fully utilise and even expand the capabilities of your operators with the help of smart tools. We also conduct feasibility studies to determine what is technically possible with respect to ROI, and what the impact on your workforce and productivity would be.

On 25 January 2024, Sirris will organise a hands-on masterclass on this topic. We will show you the way with digital work instructions and their integration in your factory. We will also show you a wide range of solutions and tools so that you can make the right choice for your company and its activities. You can also experiment yourself, with explanations provided by our experts. Practical information and the option to register can be found in our agenda.