Microfluidics in industry

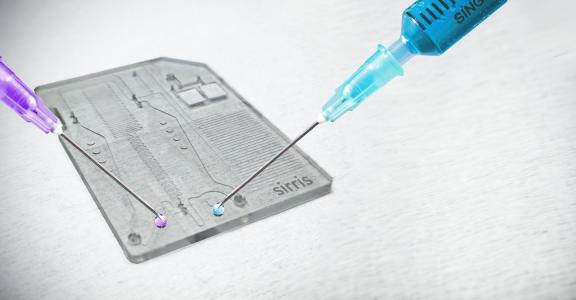

In many industries test samples are taken on a regular basis to check or analyse their composition. These samples take a whole course, from collection to appropriate action, which takes up (too) much time and resources. Thanks to microfluidics, these process steps can now be carried out on a “lab-on-a-chip” (LoC), at the point of collection, even by non-experts.

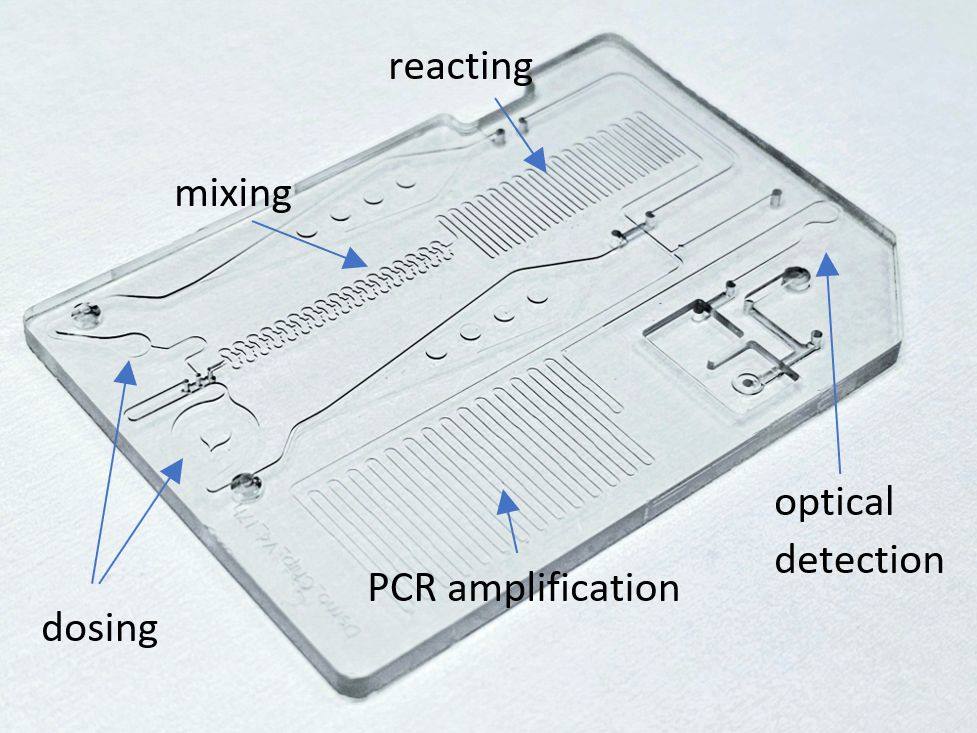

In several sectors such as medical, food, environmental or chemical, test samples are taken on a regular basis to detect contaminants or disease-causing agents ("targets"). Usually, these samples take an entire route, first from the place of collection to a central lab, then they are manipulated during various process steps, such as sample preparation with accurate dosing, mixing with reagents, heating, ..., up to the final step where the target is detected and quantified. Then, this test result is communicated back to the collection site for appropriate action. All of this can take a lot of critical time and resources.

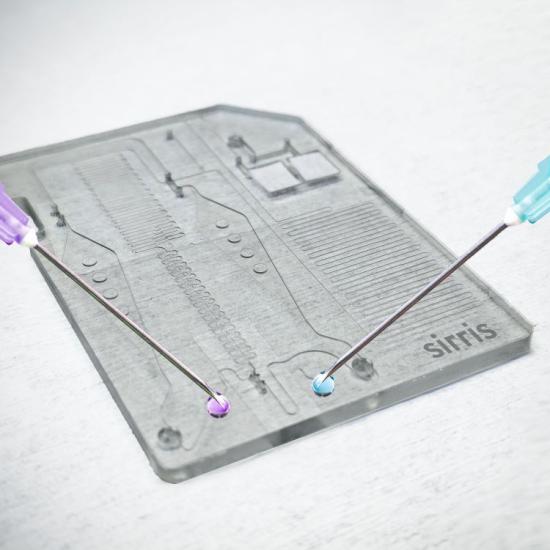

Thanks to microfluidics, these process steps can now be carried out on a “lab-on-a-chip” (LoC) the size of a credit card. This allows analysis to be done at the point of collection, even by non-experts, and using only a fraction of the sample quantity and reagents needed for analysis in the lab. Working with microliters instead of millilitres also significantly reduces the reaction time, making results available after minutes rather than after hours.

Many applications can in this way be miniaturised

In the medical sector, patient samples can be tested at the patient’s bedside for the presence of specific bacteria or viruses (e.g. a LoC Covid PCR test). Specific genes associated with diseases such as Alzheimer's, or other biomarkers that can identify a specific pathology, (such as a specific cancer) can also be detected immediately after sample collection.

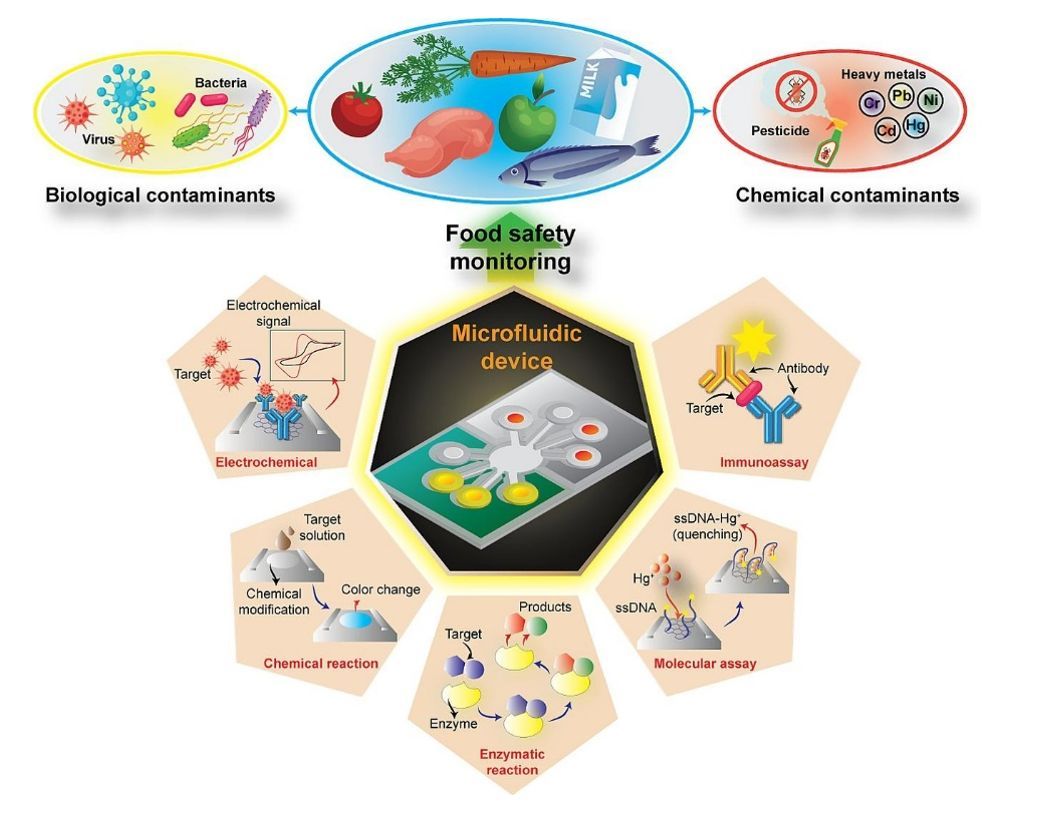

Lab-on-chips can also be used outside the medical sector:

In the food sector, pathogens (such as bacteria and fungi), chemical contaminants (such as pesticides) and allergens (such as gluten) can be detected in food products, whether at harvest, during processing, in the store or at the consumer's home. Also chemical or physical properties (like pH or viscosity) can be measured on this microfluidic scale.

For environmental testing, rapid microfluidic tests can measure the quality of drinking water or water in rivers and oceans. Detection and quantification of heavy metals, nitrates and pathogens are all examples that have already been worked out at a lab-on-chip level.

Beyond testing

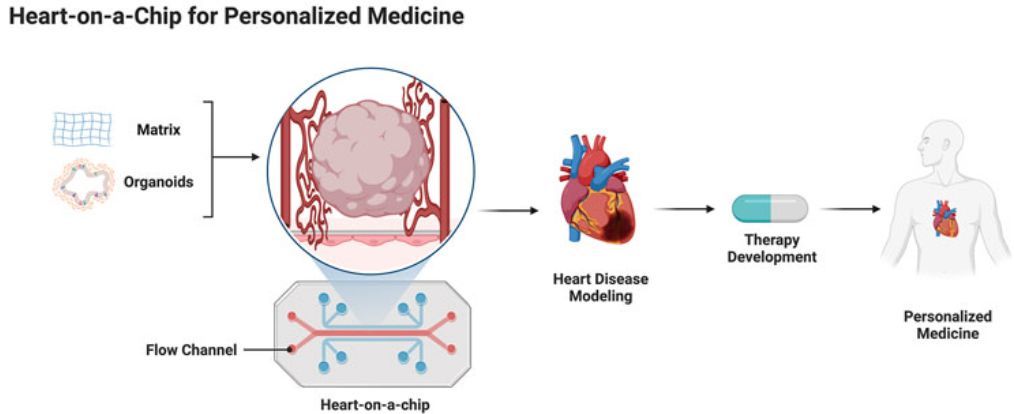

Next to testing, microfluidics can also be used for production, like in microchemical reactors, for the production of microcapsules, for growing organoids, ... With these human organoids made from the patient’s own organ or stem cell, the impact of different therapies can be tested in the microfluidic chip instead of immediately on the patient.

These are just a few examples, but any lab process is a potential candidate to be miniaturised, in cases when it is important to be able to respond quickly, without specialised personnel and without sophisticated and expensive equipment.

In subsequent articles, we will go further into the design and production of a lab-on-chip system. Knowledge and production facilities are available here in Belgium, to develop and produce these products locally. We would be happy to help you get started with your idea.

Project funding

VLAIO COOCK Medical diagnostics goes micro and smart, HBC.2021.0560

More information about the project

Medical diagnostics goes micro and smart

Reading tips on the topic

Alhalaili, Badriyah & Popescu, Ileana & Rusănescu, Carmen & Vidu, Ruxandra. (2022). Microfluidic Devices and Microfluidics-Integrated Electrochemical and Optical (Bio)Sensors for Pollution Analysis: A Review. Sustainability. 14. 10.3390/su141912844.

Deliorman, Muhammedin & A., Dima & Qasaimeh, Mohammad. (2023). Next-Generation Microfluidics for Biomedical Research and Healthcare Applications. Biomedical Engineering and Computational Biology. 14. 10.1177/11795972231214387.

Filippidou, Myrto-Kyriaki & Chatzandroulis, Stavros. (2023). Microfluidic Devices for Heavy Metal Ions Detection: A Review. Micromachines. 14. 1520. 10.3390/mi14081520.

Wang, Ting & Yu, Cecilia & Xie, Xing. (2020). Microfluidics for Environmental Applications. 10.1007/10_2020_128.

K.R. Jolvis Pou, Vijaya Raghavan, Muthukumaran Packirisamy, Microfluidics in smart packaging of foods, Food Research International, Volume 161, 2022, 111873, ISSN 0963-9969, https://doi.org/10.1016/j.foodres.2022.111873.

Sridhar, A., Kapoor, A., Kumar, P.S. et al. Lab-on-a-chip technologies for food safety, processing, and packaging applications: a review. Environ Chem Lett 20, 901–927 (2022). https://doi.org/10.1007/s10311-021-01342-4

Thi Ngoc Diep Trinh, Kieu The Loan Trinh, Nae Yoon Lee, Microfluidic advances in food safety control, Food Research International, Volume 176, 2024, 113799, ISSN 0963-9969, https://doi.org/10.1016/j.foodres.2023.113799