For many products reuse, repair, remanufacturing, repurposing and upgrading may offer a significant potential benefit in terms of value preservation and reduced environmental impact. These inner circles/strategies of the circular economy remain underutilised. For the purpose of simplicity, in this context we use 'remanufacturing' as a generic term for these circular strategies.

Manufacturing companies looking to embrace these forms of value retention are faced with a lot of questions and uncertainties. As with all innovations and adjustments or expansion of business activities, the start-up phase is challenging and crucial. Once on your way, it often becomes clearer what you need to focus on for the next steps forward.

When starting up, a lot of questions need to be answered and you have to make choices. Typical questions are:

-

Which of these inner circles (strategies) make the most sense for my product and market?

-

What new elements and challenges do I have to solve to provide remanufacturing solutions compared to what I am already doing?

-

Which revenue model makes most sense in my context?

Need for structured approach

To answer these questions, it may help to simplify. The aim of simplifying is to ask the right questions at the right time. By definition, simplifying is never quite right, but also never quite wrong. It helps you find a workable path in a complex new domain, and manage the associated risks.

The approach we propose is based on the strengths and competences already present in your company. Building on what is already there is easier than starting from scratch. On top of that, this approach ensures that faster traction and enthusiasm is generated within companies, which makes them take steps forward. In addition, we help you map out for which new key areas knowledge building or cooperation should be prioritised.

For this purpose, we have divided remanufacturing strategies into a number of 'Archetypes'. The idea is to explore where your business connects most via recognisable blocks. By definition, these archetypes are neither right nor wrong. It is possible that your remanufacturing idea fits into more than one archetype. Use these archetypes to ask the right questions for your business and discover your strengths and further improvements. It can also help you find potential partners.

The five archetypes in a row

Parts harvesting: Companies that 'harvest' valuable parts from discarded products to sell them back, typically through web platforms or other sales channels. The availability and delivery time of parts at a lower cost is the attraction for customers.

OEM repurchase and re-sale: Original equipment manufacturers (OEM) that buy back their own products from customers after the initial use phase. This often concerns quite complex or expensive products that the company resells after remanufacturing (possibly with upgrades or customer-specific customisation). It allows customers to buy high-quality products (premium brands) more cheaply.

Remanufacturing as a contractor: Organisations that remake, upgrade, or harvest the valuable parts of products on behalf of customers after their initial use phase, typically through long-term contracts. The contractor is paid for the volume they process. The quality of service is according to what customers are looking for: turnaround time, capacity, predictable and fair costs ... So, in this case, the value of the reprocessed products is determined in the contract with the customer.

Remanufacturing /Refurbishing of products in central workshop: These companies focus on project-based remanufacturing, refurbishing ... often of specific products. Typically, a unit price is calculated per project and may depend on the condition of the product that is presented. Customers come to these organisations because they have a specific need and are looking for an expert who can extend the life of their product. Clients typically have a technical installation in which the product to be remanufactured performs an important function.

Repair or upgrade of products ("assets") at the user’s premises: These companies focus on repairing or upgrading products at customer sites. Choosing to provide this service at the customer's premises is mostly related to the cost and time involved in shipping the spare parts. In this case, customers are mainly looking for a quick intervention, as well as the additional functionality that the upgrade can deliver.

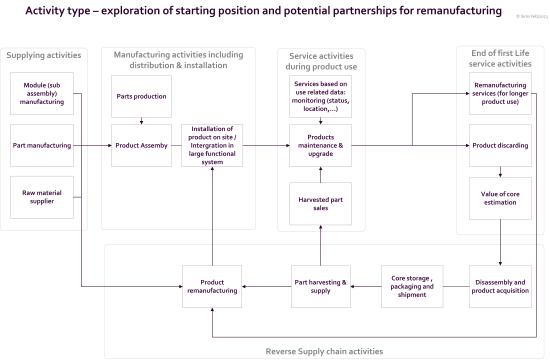

The position in the value chain determines what info is available to you

Besides the archetypes, you can also start from the position that you occupy in the value chain. A schematic representation reveals the interrelationships between actors. Some actors are in direct contact with each other; others operate in almost completely separate worlds. Establishing new relationships or collaboration may be necessary to enable remanufacturing.

The three stages of remanufacturing

Three essential stages apply to each of the archetypes. Consequently, there are also three domains on which to collect information and data when developing your remanufacturing idea.

Product inflows (cores): In this first step, it is important to get an idea of the volume, the quality of products after their first use phase, and how collection can take place. These elements will give you an idea of the pool you can use and for which your remanufacturing activities can provide added value.

The remanufacturing process: The operational activities you need to perform to actually capitalise on the potential added value as well. This includes incoming inspection, cleaning, disassembly, repair, re-assembly, testing, packaging, etc. In this case, you obviously want to generate high quality while controlling costs (working efficiently). For example, you may want to detect as early as possible whether remanufacturing of a core still makes sense.

The outflow of products and or parts (sales): the reprocessed products and parts must be monetised optimally, including the elements of distribution, pricing, payment service... In this stage, you want to get a view of the market demand, which customer segment wants to exploit your products and services.

The exploration tool that brings everything together

For each of these three remanufacturing stages, you can identify your assets and opportunities.

To help you with this, we have combined the archetypes with the three process steps in one template.

With this tool, you can:

-

Select the archetype that best suits your remanufacturing idea. We described the value proposition, customer type and typical revenue model for each archetype to help you identify the most valid archetype.

-

For each archetype, you can identify your competences and assets, as well as your challenges or topics for further improvement.

-

Finally, the table and the process flow (see image) also provide starting points for linking competences and challenges of other actors in the value chain to your own. This will help you identify partners who can help realise your remanufacturing idea.

Call for follow-up steps

The aim of the proposed tool is to provide support in your exploration of remanufacturing. Perhaps you have suggestions to further improve or complement the tool? We look forward to hearing your feedback on this approach and tool!

Remanufacturing, repairing, repurposing, refurbishing, reusing, ... are all valuable circular strategies. The question is how to be sure that you are exploring and testing the most optimal strategy, specifically for an SME context? With the COOCK project "CIRCLE - Remanufacturing as a lever for value creation in a circular manufacturing industry", with the support of VLAIO, Sirris provides you with an approach and practical tools (technologies, tools ...) to help you limit the risks and increase the chances of success.