15´ webinar - How to control a complex AM part in shape and dimensions

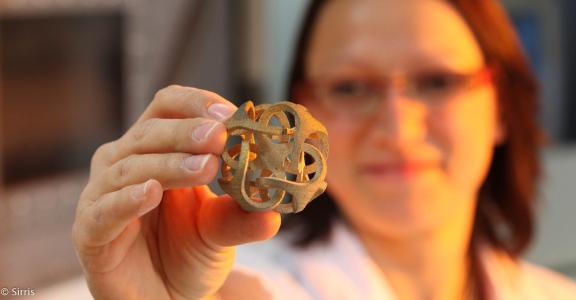

Additive manufacturing (AM) simplifies the production of complex, material-efficient and lighter parts, optimises flow applications and makes freedom of form possible. At Sirris, we not only bridge the gap between technology and industry and guide you through every step in AM, but we can also help you with the quality of your AM process or product.

Sirris can help you to guarantee the quality of your AM process or product, by:

- Identifying the variables to be controlled to guarantee the quality of your product throughout the AM value chain, including heat treatment step.

- Helping to exploit the available data for the purpose of traceability, understanding drifts and their prediction.

- Supporting your quality process with our AM oriented laboratories: materials characterisation - thermal analysis & powder properties, heat treatment lab, metrology lab.

To get you acquainted with these possibilities, our services and (new) equipment, Sirris organises this new series of short webinars, consisting of a brief introduction, concrete workshop videos, showing examples and case studies, to end with an open questions and answers session with our experts.

During this second webinar we make the link between design, manufacturing constraints and dimensional control at the process output: we explain what the principal applications of optical metrology are, how we apply this technology to control a complex AM part in shape and dimensions, and the link with process simulation in deformation. By doing so, we improve the final quality of a built part in terms of geometric accuracy. Thanks to an optimal software calibration based on 3D scans of real parts, we can compensate the geometry to reach the best tolerances, considering manufacturing, heat treatment and final support removal.

Interested in the bigger picture? During our masterclass ‘Integrating additive manufacturing in your business’ on 16 March 2023, we offer you a complete overview of the current trends in AM, both in terms of products and techniques. We also give you the keys to understand the different families as well as their strengths and weaknesses. Register now!