Tool monitoring is needed in the milling process in order to be able to automate it and to ensure the quality of the products. This is not an easy task where micromilling tools are involved, but acoustic sensors can offer a solution for this.

An undetected tool fracture can lead to unusable products and even damage the spindle of the machine. An experienced operator can immediately detect any problems by looking and hearing. However, with small cutters - with diameters less than 1 mm, for example - this is not always possible. The sound from the machining process is inaudible in a noisy workshop and the tools and workpieces are so small that it is almost impossible to see whether a cutting edge is still present, especially if a coolant is used.

Acoustic sensors can be used to monitor these micromills. The more traditional signals (forces, spindle power) are insufficient to distinguish the process signal from the noise, but with high-frequency vibration data the detection can be automatic.

Automatic Tool Wear Inspection

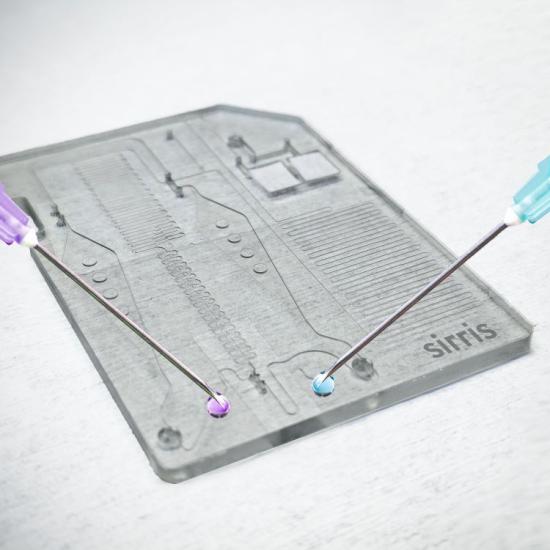

Within the ICON project 'Automatic Tool Wear Inspection', Melotte collaborates with Sirris and other partners on the use of acoustic sensors. The aim is to estimate not only tool breakage but also the wear itself during the process. This makes it possible to intervene in time and thus set up a process monitoring system.

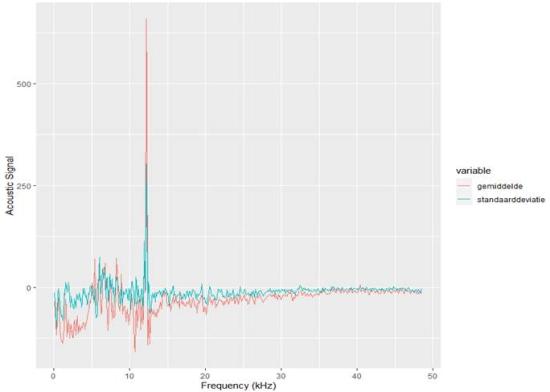

The project also investigated how the detection sensitivity of the sensor depends on whether it is on the workpiece, the spindle or the clamping system. An acoustic sensor needs a wired connection to be able to process the high data frequencies, and it is important to be able to install this on a machine. It turned out to be possible to recognise the signals regardless of whether the sensor was on the workpiece, the clamping table or the spindle. This allows for a practical implementation. The following figure shows the signals (relative to the noise) during the process when placed on the clamping table.

The following periods will see further research into relating the sensor data to the wear, the use of other acceleration signals that can be processed wirelessly and the use of vision as a monitoring system.

This project receives support from the VLAIO. You can read more here.

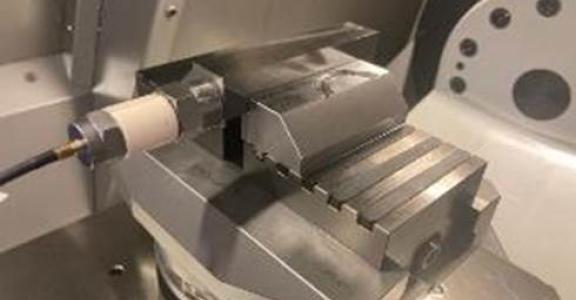

(Picture above: A sensor on the workpiece)