By integrating digital tools, operators can quickly access the right, relevant knowledge while performing their tasks. As a company, what exactly should you expect from this type of systems? What are the technological possibilities and what jobs can they handle?

For several years now, the use of digital work instruction systems has been on the rise. A logical evolution, given that they seem to respond seamlessly to contemporary trends and needs. There is a growing need for efficient support to operators in their rapidly changing and expanding range of tasks, and this is where digital tools can provide a solution.

In any case, digital instructional systems should be more than just a digital copy (e.g. in PDF format) of the traditional instructions on paper, as we pointed out in a previous article. Digitisation only reaches its full potential when you make digital instructions better than paper instructions. Digital instructional systems surpass paper-based instruction as they offer the following functionalities:

- Clear visualisation of the active step: employees can get lost in instructions and skip steps. Showing or highlighting only the current step makes it easier to follow instructions consistently.

- Simplified logics: instructions with conditional steps - "IF X, THEN..." - and instructions with logical operators ("AND" and "OR") are difficult to follow. Digital instructions with guided questions can simplify this by eliminating operator reasoning. In that case, the system will simply ask "Do you see case X or Y?" Based on the choice, only the appropriate instruction is displayed.

- Component verification: digital systems may request that a component's code be scanned in first. If the correct component is not offered, then the instruction stops, and the employee must first search for the correct component.

- Computational help: measured values often need to be compared with prescribed values or simple calculations need to be done. This is error-prone work that computers can easily take over. It then suffices to enter the measured value, after which the instruction system will perform its own check.

- Interface with other systems: by linking digital work instruction systems to, for example, an ERP system, the correct instruction can be retrieved automatically and the employee does not have to look up the instruction. Linking also allows easy retrieval of data (e.g. drawings) from other systems.

- Secured effective use: in the past, we saw processes where paper measurement sheets were already filled in even before production had taken place. The effective use of digital tools can be easily verified with the digital timestamps.

- Enriched instructions with pictures, animations and videos: adding pictures, and especially animations and video allows for faster and better understanding of the instruction.

- Interactivity: digital tools enable better interaction with instructions by enabling, for example, zooming and rotating 3D models.

For which tasks?

Digital instructions are most appreciated in jobs where errors or oversights are difficult to rule out, such as complex assembly operations, jobs where the sequence of operations is critical, operations where tool setting parameters must be correct or where specific safety or quality instructions must be followed, in case of large product variations due to extensive options ...

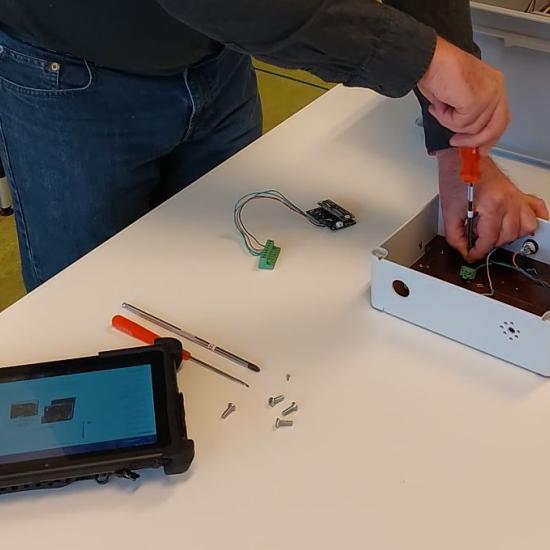

Even in companies with more or less standard products, except for seasonal production capacity or rotating staff, digital work instructions are valuable as a training tool. Another application lies in assembly or maintenance work 'in the field'. The work instruction then becomes an electronic instruction booklet on a mobile device.

Digital work instructions in your business?

Interested in how integrating digital work instructions can also make your operators (even) better? On 31 January, Sirris is organising a hands-on masterclass about this topical topic. We will tell you all about digital work instructions and how to integrate them in your plant. We will show you a wide range of solutions and tools so you can make the right choice for your business and operations. It will also give you the chance to experiment and get the necessary explanations from our experts. Practical info and the possibility to register can be found in our agenda.