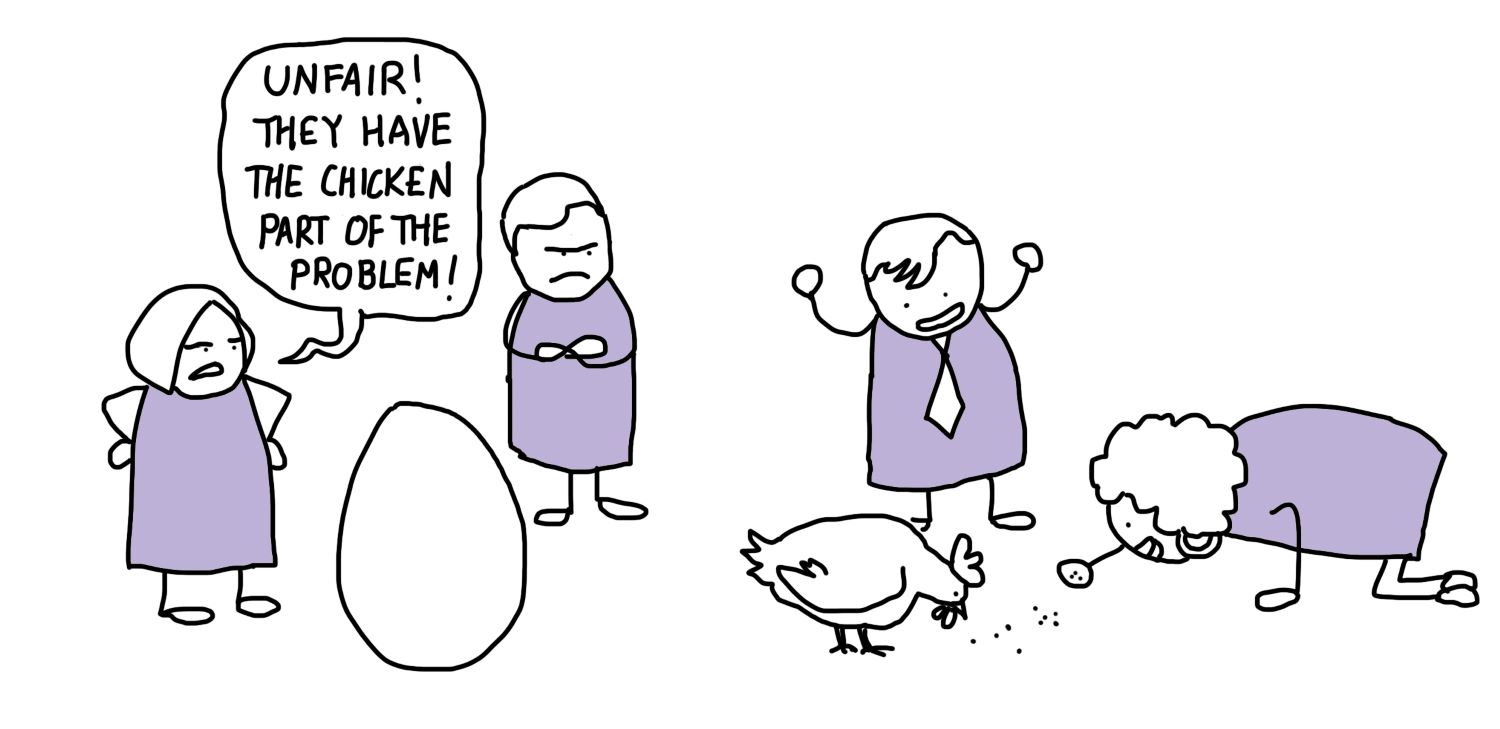

Lock-ins and interdependencies: the chicken or the egg? (Part 1)

Every organisation involved in the practice of the circular economy has to face it: situations that end up being a stalemate, where external factors have to change first before we can move forward, where different parties are waiting for each other because they are interdependent. For some, there is no demand for products and services that pursue circular goals, for others the supply of products and services that contribute to the circular economy is not enough. How can we overcome this?

You want to market circular products and services, but customers are not prepared to pay the higher cost associated with this. Do we need to increase customer demand or improve supply?

You want to engage in collaboration to reuse discarded products, but regulations do not allow it. Should the regulations change or should products not turn into waste after use?

There are many of these chicken-and-egg situations, which may give you the impression that no progress can be made. However, there is a way forward.

The first method is to wait. If you do not want to be one of the forerunners and early adopters, you can choose this option. But by doing so, you will miss opportunities to adapt your organisation to the new reality early on (survival of the fittest).

Break the vicious circle

In practice, solutions can usually be found for such lock-in situations or chicken-and-egg situations, which can deal with the situation and even benefit from them to make circular business operations more robust and powerful.

We learned from experience, and we also see that the leading companies are adopting this approach.

First, zoom out and look at the situation from a distance: are you the chicken or are you the egg?

Chickens can change their perspective due to their freedom of movement

If you are the chicken, you still have some freedom of movement. You do not have all the knowledge, but you can move around and adopt a new perspective. That is, by looking at the situation differently, you may actually be able to assess it differently. This is how new opportunities and relationships, which were previously invisible, will emerge. This situation is essentially similar to the pivotal moment during the iterative setting up of your circular initiative. A process that progresses through three repeated phases:

- Come up with and set up an assumption.

- Test and validate the assumptions.

- Learn and decide what the next step will be (in the same direction if successful or in a different direction if the result is different from what you’d expected).

An example: I cannot know my remanufacturing process (process steps, cost ...) until I know the quality of the incoming cores (discarded products). I cannot know the quality of the incoming cores until I have inspected them, dismantled them ... So I need to act in function of what I want to know, and vice versa.

This is where we recognise a recurring approach among organisations which break through these situations. In short, it is about deploying an iterative approach.Typical steps in this approach are based on the following questions:

- What is already available in terms of knowledge and information?

- What assumptions are we making?

- How do we test and assess them?

- What can we learn from this?

Applied to the example of setting up a remanufacturing process:

- What is already available in terms of knowledge and information? In most cases, you have knowledge and data from the product, its useful life, possibly from design data, previously delivered services, upgrades ...

- What assumptions are we making? Machines older than 10 years are not really suitable for upgrades. Products based on a particular technology X are not appropriate for remanufacturing.

- Test and assess these assumptions: we take back a few machines older than 10 years and inspect them. What preconditions (via a study based on the product design) are there to still upgrade or repair products (or product groups) with technology X?

- What can we learn from this? What combinations of data, age and technology determine which remanufacturing steps (inspection, testing) are necessary? What are the stricter criteria for procurement cores?

Based on this approach, you can adjust assumptions, take a new path, steer ... These are your pivotal moments.

The key trait we see in the teams that manage to take these steps and continue to make progress (which is often in a modified direction) is entrepreneurship or intrapreneurship. They are the initiators, the leaders, the doers, the people who look for opportunities and those who reduce uncertainties and (thus risks) step by step.

Hence the importance of putting together the right team, which you can also read in Moduar Lighting Instruments' testimonial.

Eggs grow from the inside out until the shell breaks and then the chick comes out

Eggs are static and non-extensible. In these situations, there is almost no margin to make immediate progress, which requires some preparation beforehand. There is still a need to put pressure on the existing boundaries. This is only possible from within. So the clue is to make ourselves and others, who are stuck in the egg, stronger.

How? Bring together the underlying logic or thought patterns (the 'mental models') of the actors involved. Question the actors about their value framework and check whether your end goal is very different.

An example: There are regulations that stand in the way of a circular approach.

Engage in conversation to learn. Write down the arguments, goals and aspirations. After the conversation, distil the underlying values. Make this analysis for yourself too and list your own underlying values. Now you have material to increase internal pressure. Scale up these values on an axis with your values on the left and the values of others on the right. In the middle, some common values may emerge. Focus on working together from the perspective of a common goal. What is the spirit of the regulations? What do you want to achieve and prevent with those regulations? What values and meaningful thoughts lie behind them?

Based on common values and aspirations, what are the steps we can take together? What preconditions or what context (pilot project, registration, documentation, etc.) can we come up with that will still allow us to take a step forward? Who has what role in this next step? One tests and documents, the other assesses and checks the preconditions.

These situations can also occur within one organisation. Typically, there are different interpretations of what circularity is and what it can mean. Ask yourself the following questions: what is a circular product or service worth to you? Why would you either or not buy a circular product or service?

An example: Your organisation is part of a large international group and the priorities and objective do not seem to coincide. Put boldly, this sounds like 'We do want to choose circular, but HQ only wants short-term profits'.

Questions you need to ask: What do we ultimately want to achieve with our organisation? What do we stand for and what is our mission? As an organisation, do we want to reduce our environmental impact? Do we want to generate additional revenue and explore new markets? What values (people, planet, prosperity) do we put first? In a similar way, you will obtain an overall picture in which the common values and objective become visible. So actively look for similarities and converging elements.

Often, you will find common goals such as lifetime extension, cost-effective solution, functionality without negative impact on environment, increased revenue without additional costs, access to new markets, increased reuse, etc.

In these cases, the egg breaks, with the approval of the chicken, who is quite excited about this new life in the form of a 'fragile' chick.

What if the chicken doesn't want a chick? We will address that in a future blog.

Want to know more about how to tackle circular lock-in situations in practice? Get in touch with us

This article was written as part of the COOCK project Circle: setting up activities focused on product life extension, and the related challenges.