How do you create reliable infrastructure in difficult conditions at sea? That was the central question during 'Reliable AC/DC infrastructures @sea', organised by Sirris/OWI-Lab, KBVE-SRBE and the Agoria Energy Technology Club. The technical seminar looked deeper into the challenges and optimal working methods involved as well as the technological state-of-the-art for electrical components, and looked at some real-world examples. Here we take a look back at the seminar.

An important element in the climate debate today is energy. Renewable energy, with wind energy at the forefront, will play a crucial role in the transition to climate-neutral electricity production. Offshore wind in particular will see tremendous growth in the coming years. Growth offers opportunities for all players in the market. Wind energy is therefore gaining momentum thanks to rapid technological developments, driven by the energy transition objectives and the associated stimulation of renewable energy systems by the EU.

300 GW of offshore wind capacity by 2050

The goals that European energy suppliers have set themselves are therefore not mistaken: according to the Green Deal, the energy transition to a climate-neutral Europe must be a reality by 2050. In addition, the grid must be future-proofed and clean electricity made available to all Europeans. By 2050, the EU aims to build up to 450 GW of offshore wind capacity, of which some 300 GW will be in the North Sea. Hybrid offshore wind farms will play an increasingly important role in achieving this goal as they will not only bring electricity directly to the land but also serve as interconnectors between countries.

Switching to HVDC networks

One way to achieve this is by using (meshed) HVDC grids. High-voltage direct current (HVDC) is today used mainly for sending electrical power over longer distances. HVDC can address some major challenges, including existing obstacles such as the sometimes difficult locations of renewable energy sources, the local concentration of energy production and the need for both long-distance transmission and cables for offshore installations. Addressing these new challenges also requires a new HVDC approach in which multiple suppliers will be involved in each project, with the aim of making DC (direct current) as easy to use as AC (alternating current). If they are to be deployed widely and across national borders, the HVDC systems must be compatible and interoperable, both offshore and onshore. We need to move away from the traditional energy delivery approach to a new one, where suppliers and transmission system operators are involved together in a single real-world infrastructure pilot project. Finally, unlocking HVDC interoperability requires a joint effort from all stakeholders.

In the opening presentation of the event, T&D Europe went into more detail on this topic and on how the two European projects Horizon READY4DC and InterOPERA are already working on it.

Dirk Van Hertem of Energyville (University of Leuven) used his presentation on innovations and opportunities associated with energy islands to explain why significant investments will be required to achieve the ambitious European objectives as well as for offshore developments and the roll-out of meshed HVDC grids. The latter currently represent the only realistic option for meeting these aims: connections are located increasingly far from the coast, the new grids must be integrated into the existing (hybrid AC/DC) system and work is needed to make a new backbone grid, preferably underground. Onshore multi-GW energy hubs will also be needed.

The Princess Elisabeth Energy Island

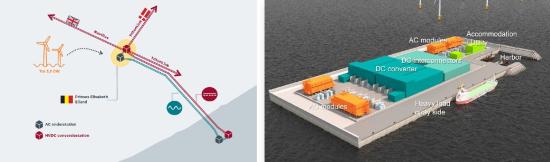

The need for HVDC solutions can be met by artificial energy islands such as the Princess Elisabeth Island, which is to be built off the coast of Ostend. Energy islands - the popular name for offshore (multi-GW) substations – interconnect different synchronous zones and renewable energy sources via HVDC cables. The grid operator Elia was commissioned by the Belgian government to design a grid to connect up to 3.5 GW of offshore wind in the new Princess Elisabeth wind zone. This would meet the Belgian aim of integrating renewable energy sources (up to 6 GW by 2030). The question was also raised of including the option of integrating interconnectors, such as Nautilus and Triton Link. To meet the set goals, a combination of alternating current and HVDC is planned.

Elia's job is to design, build and operate the new and expanded grid infrastructure for connecting additional wind farms, which is being done with support from the European Union.

To meet this request, the Princess Elisabeth Island is planned to enable:

- The integration of renewable energy generated in the Belgian North Sea zone into the Belgian and European electricity system.

- Provision for connecting future interconnectors, allowing access to additional renewable energy, generated beyond the Belgian North Sea zone.

- Maximum flexibility for accommodating a future North Sea network.

|

Opportunities and innovations linked to energy islands

In his presentation on the innovations and opportunities for the energy island, Professor Dirk Van Hertem of Energyville discussed the challenges of energy islands in terms of design, operation, protection and control. The main stumbling blocks to be overcome are:

- The energy balance, in different time frames

- A rigid system with poorly damped harmonics and voltage fluctuations

- Topology and protection

- Design, including whether a connection is provided on the AC or DC side, the maximum connection speed, ...

- Common mode defects

- Management and maintenance (M&M)

- Uncertainties about ownership, market integration and operational control: these islands could be managed independently

In his presentation, Bart Callens of the Belgian consortium TM Edison (Jan De Nul and DEME) expanded on the challenges in the design and construction of the energy island. The main challenge is the timing: the construction of the island started in February 2023 with the conclusion of the contract, and the end of the works is scheduled for 31 December 2026. The installation of the island will be divided between the summers of 2024 and 2025. If the work in the preparatory phases is delayed and the summer of 2024 is missed for the start of the implementation, this work must be moved immediately to the following summer, putting everything a whole year behind schedule.

A second challenge concerns the cable landing points: the design, the means to protect the cables underwater for at least 50 years, the stabilisation of the cable, etc.

To meet these and other challenges, the partners have chosen optimisation during the early phase, from costs, timing, risk reduction, environmental impact, quality, ... The aim is also to integrate the energy island into the environment as far as possible through the implementation of a 'nature-inclusive design' (NID).

Modular Offshore Grid: lessons learned and challenges

Tanguy Petrè explained how Elia is converting the experience it has gained in installing and operating the offshore transmission network into lessons learned for expanding this grid to connect the Princess Elisabeth zone and the energy island. The Modular Offshore Grid (MOG I) - the first Elia project with an offshore switching platform - has been operational since 2019. This platform - the 'Offshore Switchyard' (OSY) - is located 40 km from the coast, where it combines the electricity from four offshore wind farms and sends it ashore via shared submarine cables to the Stevin high-voltage substation in Zeebrugge. Thanks to the MOG, renewable energy is optimally integrated into the Belgian electricity grid.

For MOG I, the sourcing strategy chosen was to use a combined multi-contract approach with OEMs and to carry out a significant part of the scope with Elia technicians. This was preferred to entrusting the outsourcing of the entire scope to a single umbrella M&M contract. The approach brought some interesting benefits, and, given the success of the MOG I strategy in both quality and cost, it was decided to do the same for MOG II.

There are specific offshore M&M challenges involved in a MOG: there has to be access by ship or helicopter, specific safety functions and training are needed, the work is very weather-dependent and requires great flexibility, the environment is rough and corrosive, ... Over the course of four years, Elia has gained a great deal of experience, and the lessons learned from this have been incorporated in the specifications of the tender for MOG II. The Princess Elisabeth Island also comes with its own specific M&M challenges, partly due to its greater size and its proximity to a port.

Cable monitoring

Roel Vanthillo of Marlinks gave a presentation about the importance and value of monitoring undersea cables. In the offshore wind industry, the cables account for 10-20 percent of the initial CAPEX costs. Nevertheless, 80 percent of the insurance dossiers for wind farms are linked to them. No fewer than 57 out of 60 construction projects had problems related to cabling. The hidden costs due to damage to these cables can escalate if action is not taken in time. Marlinks proposed three possible forms of monitoring:

- Via a fibre optic cable, which is present as standard in HVAC cables. Its main purpose is data communication but it can also be used as a sensor.

- DTS (distributed temperature sensing) and applications: temperature measurement via a fibre optic cable.

- DAS (distributed acoustic sensing) detection and applications: a powerful new tool for comprehensive asset monitoring by continuously measuring sound signals along the full length of a fibre optic cable.

A practical example: EME

The EME presentation 'Designing for operational reliability’ described a practical case of an electromechanical design 140 metres above sea level. Among other things, EME develops isolating switches (unloaded) tailored to the needs of the customer. These switches are safety elements in MV drives and converters: they are used to switch off the grid for visible isolation, for earthing a DC bus and for discharging power capacitors. Typical isolating switches in wind converters are intended for grid interruption (3p 2000 A), the discharge of capacitors (6p), the grounding of a DC bus (3p) and the disconnection of generators (3p 2000 A).

There are some specific design and development challenges related to the fact that they are located inside the nacelle: limited space, an environment characterised by heat, vibration, corrosion and cold start-up and the need for designed-in reliability and short shutdown times. It must also be possible to produce them in large series and there needs to be a specific electrical design at a low frequency, with the use of less copper. All these challenges were tackled individually with the help of Sirris.

|