PROCOPIDO | Connected Manufacturing Controlled by Data

The PROCOPIDO project aims to help manufacturing SMEs to be capable of initiating new applications controlled by data acquired in (quasi) real time more easily and at least cost.

Context

The abandonment of mass production to the benefit of small runs of made-to-measure complex products, with high added value and short lead times, is involving increased production complexity in Walloon manufacturing companies. As a result, productivity is under pressure. Furthermore, pushed by customers or suppliers, companies are having to look to transforming their business models (new products & services).

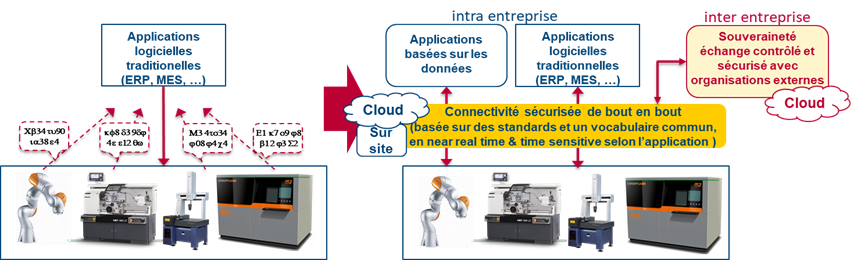

Hence, companies are having to become more agile and ensure that the right information is conveyed to the right person at the right time, which is helping to decentralise decision making and to reorganise the value chain. Most Walloon production shops use software applications (ERP, MES, etc.) which send manufacturing orders to the shop floor in one-way communication mode. This is undeniably not sufficient. Nowadays companies want to be capable of easily connecting their production system in two-way communication in order to extract or inject data and to allow everyone access. They also want to be able to exchange data securely with external partners and preserve their sovereignty. In some cases, real time communication is wanted.

This is simple to resolve when all the machines are recent and come from the same constructor, but it is not yet resolved and much more complex when the company is strategically positioned with a set of heterogenous machinery (makes, types, age, each one having its own connection options and its own vocabulary of settings) and has diverse sources of disconnected data (sensors, ERP, MES, QMS, CFAO, Excel, etc.).

Objective

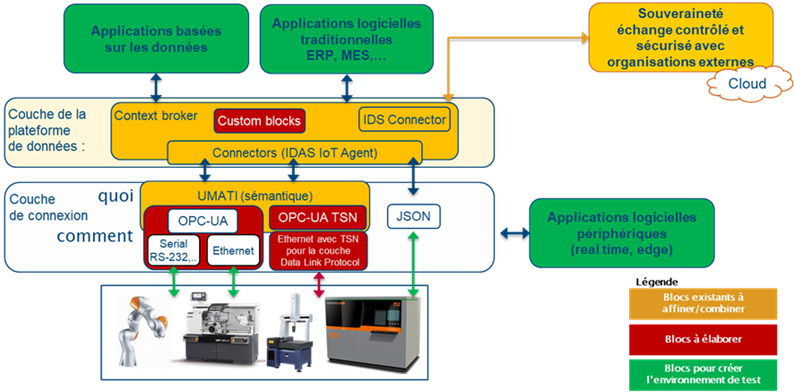

The PROCOPIDO project aims to develop a concept of modular flexible and extendible architecture which can be implemented gradually (from simpler to more complex). The result expected is the supply of solutions that are open, modular and combinable which is based on the international standards I4.0 to ensure (quasi) real time connectivity with end-to-end security and technical and semantic interoperability in a heterogenous equipment and software space typical of manufacturing companies.

Approach

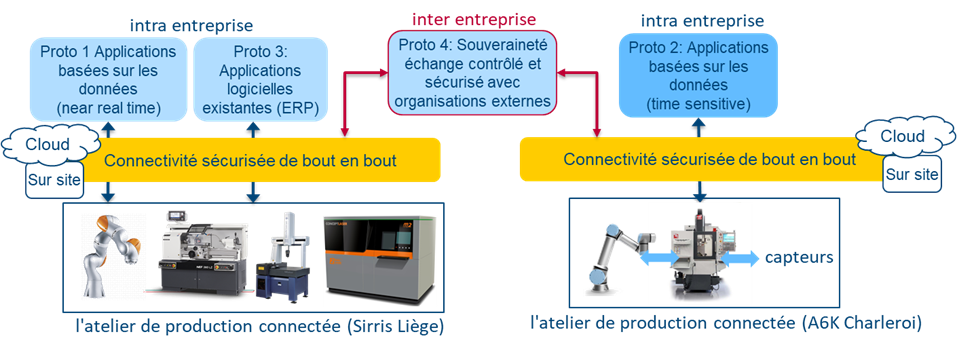

To start, with use cases representative of manufacturing SMEs and machine constructors, the connectivity solutions developed are being put into action in four representative pilot cases with a dual goal. One, to provide proof of concept and two, to provide a tool for raising awareness and learning of the technical possibilities for all interveners of the value chain.

The project will close with the finalising of workshop concepts and training paths to encourage the speedy acquisition of knowledge by SMEs and allow everyone to try out these connectivity solutions.

Target group

All stakeholders of the value chain are concerned by the results of this project, whether machine constructors, ERP/MES suppliers, manufacturers of intelligent components, developers of digital platforms and applications based on data, and of course manufacturing companies. All these actors are represented in the project steering group. They supply data for the specification of typical applications and provide representative use cases. They are ensuring that the results of the project make sense with the challenges they are facing to cope with the data silos. Members of the steering group are the first to acquire the knowledge.

Reference

- Win4Collective 2022 – N° 2210079 – PROCOPIDO