An innovative, plasmonic paint system uses nanoparticles to create structural colours without the need for multiple pigments. This system, which needs less product and is more colour stable, is also more environmentally friendly, lighter and cheaper than traditional paint systems.

Today, paints owe their colour to the presence of pigment molecules, which absorb certain wavelengths of light and reflect others. However, researchers at the University of Central Florida have developed a completely new type of paint inspired by butterfly wings. These plasmonic paints use nanoparticles to create different colours without the many pigments normally required.

The main disadvantage of traditional paints is that you need a new pigment molecule for each colour. In addition, some pigment molecules are rare or toxic, such as the popular cobalt blue. This is a mixture of cobalt oxide and aluminium that is dangerous if inhaled or ingested.

Plasmonic nano system

That is why researchers looked for an alternative and were inspired by butterfly wings, which have structural colour as a characteristic. In this, the geometric arrangement of colourless materials can reflect, diffuse and absorb light to produce different colours. The newly developed paint works similarly, using aluminium and aluminium oxide nanoparticles to create a plasmonic nano system that makes it possible to manipulate light in a unique way.

The researchers created the base material by coating a mirror with nanoparticles. The distance between the particles determines how the material interacts with light to create the colour we perceive when we look at it. To turn these surfaces into paints, the entire structure was applied onto a sacrificial layer, so that it could then be removed and ground into a powder. This produced a highly reflective pigment based on pieces of plasmonic material. These particles were then mixed with a commercially available binder.

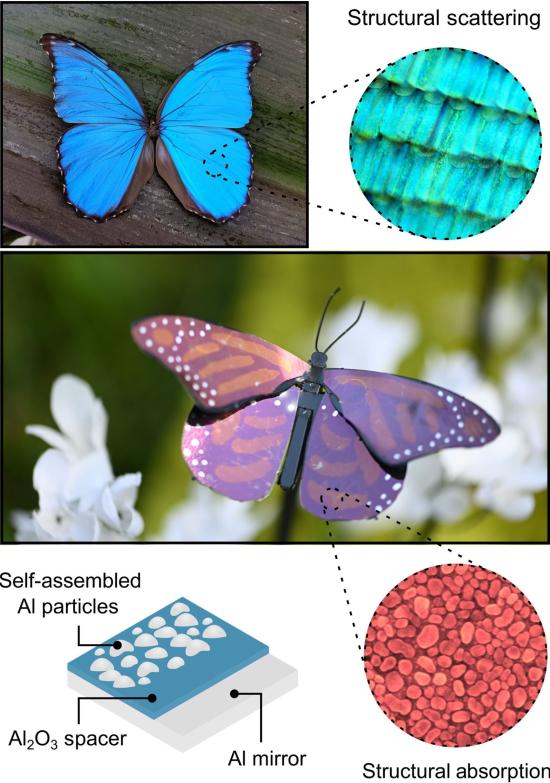

Above: Structural colouration in the wings of the Peruvian Morpho Didius, where lamellar nanostructures in the wings scatter the blue components of incident light to generate the characteristic metallic blue colour. Below: Subwavelength-scale plasmonic cavity on the surface of a metal butterfly, formed by self-assembly of metallic nano islands on an oxide-coated mirror, generates colour by selectively absorbing some wavelengths while strongly reflecting others (Source: University of Central Florida)

The technology is highly reproducible: the aluminium particles are made by a temperature- and pressure-dependent process whereby a thin film grows under a high vacuum via evaporation by an electron beam (e-beam evaporation). The plasmonic surface formation process is compatible with any substrate and takes on its light-scattering properties.

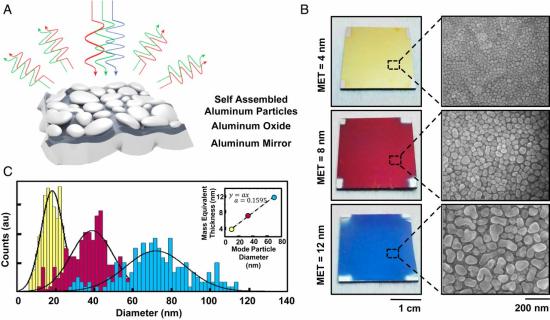

(A) Diagram of self-assembled aluminium particles on top of an oxide interlayer and aluminium mirror. Wavelength of plasmonic resonance scales with particle dimensions.

(B) Camera images and SEM images of three samples corresponding to yellow, magenta and cyan.

(C) Histogram of particle sizes obtained from the SEM images: the radii for the particles are calculated by assuming a surface-equivalent sphere

(Source: University of Central Florida)

Advantages

Traditional paints fade with time as the pigment molecules lose their photon-absorbing properties. This problem does not occur with the nanotech paint: the nanoparticles do not change with time - they refract the light in the same way, regardless of the angle of incidence. Once a surface has been given structural colour, this colour is retained and remains vibrant, in principle forever. The coloured surfaces are also stretchable and flexible.

The structural colours are more environmentally friendly than traditional, pigment-based colours because they only use metals and oxides, and not artificially-synthesized molecules.

Furthermore, the paint is not only very light, it also has a large surface-to-thickness ratio, meaning that less is needed to get the job done: full coloration is achieved with layers no more than about 150 nm thick. This means, for example, that painting a Boeing 747 would require less than 1.5 kg of plasmonic paint instead of more than 450 kg of standard paint.

In addition, the plasmonic paint reflects the entire infrared spectrum, leaving less heat to be absorbed by the paint. As a result, the underlying material remains about 15 °C cooler than with commercial paint. This property can reduce the energy needed for cooling, for example when used in the construction or transport sector.

Future

This development opens the door to many applications and potential markets for plasmonic nanostructures. The research team is planning further research into the possible energy-saving properties of the paint and wants to prove that it is a commercially viable product. Currently, plasmonic paint can only be produced in small batches in a laboratory, while commercial paint has to be produced in much larger quantities.

|

Innovation in surface technologies

Similar technologies and their feasibility, potential and possible range of application are also being investigated and developed at Sirris. Every day, our experts are looking for coatings or surface treatment technologies that are suited to a circular economy or less detrimental to human health and the environment than existing systems. Examples of these include bio-based coatings and textures as described in this article.

You can find more information about these and other functional surface techniques in this brochure.