Over the years, various calculation models have been developed that allow machining processes to be analysed and even optimised. These calculation models can be run by anyone on the online platform modelgebaseerdbewerken.be by means of simple forms. In a series of blog posts, we explain how you can use this platform in practice. In this fifth part, we look at how you can estimate your processing costs within a matter of seconds.

Drawing up a quotation for a new workpiece is time-consuming because you need to understand the product drawing in order to identify the challenges involved in the production process. If you overlook or underestimate an important aspect (a tolerance, a level of finish, …), you will probably bid too low and, naturally, win the order. At best, the mistake will come to light during production and a lot of effort will be needed to save the already tight margin.

These situations could be avoided if there was a quick way to check the newly calculated price against - preferably similar - projects from the past. (If the new calculation deviates too much from the historical data, an extra check is recommended before submitting your quotation.) The 'Cost Estimation' model lets you do precisely this - and within seconds!

Cost estimation

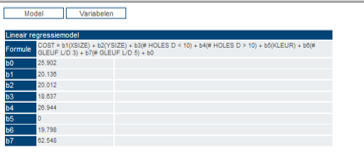

The model calculates a formula for you that best approximates the actual costs. To do this, you need to upload the data of past projects. This data consists of the price of the previous project and a list of cost-determining parameters. The latter might consist of the X, Y and Z dimensions of the workpiece, the number of fits, the number of holes, the amount of material to be removed, etc. Since you probably don’t know exactly what the cost-determining parameters are at the start, it is best to upload as many of them as possible. As soon as the data is loaded, the model will determine your cost formula via linear regression and immediately indicate the determining parameters. If a new quotation is requested, you only have to enter these parameters in the formula and the cost price will be estimated automatically.

An example

In the example below, the factor b5 associated with the parameter 'COLOUR' is zero, which means that the parameter does not contribute to the processing cost. Factor b4, on the other hand, is very high, which means that the parameter 'number of holes with a diameter greater than 10 mm' is cost-determining.

The published model uses only linear regression analysis to determine the cost formula, which limits its accuracy. The formula obtained should therefore only be used to check your own, detailed calculation. The fact that the formula uses recalculation of actual historical data means that all the hidden costs are included and that the formula is quite specific to your company, method, applications, etc.

Tip: limit the scope of the formula to the processing costs and leave the material costs aside for the moment.

Modelgebaseerdbewerken.be

Access to the platform is free of charge, but you do need to register.

- Step 1. Register via the Sirris portal

URL: https://portal.sirris.be/modelgebaseerde-bewerken-login

Important: The code is generated immediately and displayed on the screen. So write it down or copy it immediately

- Step 2. Go to the online platform

URL: http://www.modelgebaseerdbewerken.be/index.php

- Step 3. Go to the login screen (top right button)

- Step 4. Log in with your e-mail address and the generated code

You will also find the necessary explanations about working with the models on the platform, but be sure to keep an eye on the Sirris diary because we will be organising both physical and online explanation sessions.

The online platform is part of the COOCK project 'Model-based processing ', which was launched with support from Flanders Innovation & Entrepreneurship (VLAIO).