The use of (real-time) data to adjust production processes - in machining the term is 'adaptive machining' - is the future of production. This is made possible by the increased availability of sensors. However, everything depends on having and understanding a standardised and structured model, in which the digital information is processed into a physical action. Such models are the key to successful digitalisation. In a series of blog posts, we highlight some basic models. In this third part, we look at a model for calculating the cutting force: the Kienzle formula.

Everyone talks about 'Industrie 4.0' or the extensive use of (real-time) data to adjust and control production processes as the future of production. Within the machining industry, adaptive machining has been talked about for years, and thanks to the increased availability of sensors, it is now within reach. However, all this depends on having and understanding a standardised and structured model, in which the digital information is processed into a physical action. Such machining models are available and are still being supplemented by new scientific insights. In industry, however, to some extent they have fallen into disuse. As they are the key to successful digitisation, we highlight some basic models in this series of articles. In this article: the Kienzle formula, a model for calculating the cutting force.

Kienzle's formula

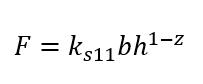

Kienzle's formula allows us to calculate or estimate the cutting forces that occur during the machining process. In its simplest form, the formula is as follows:

wherein ks11 is the specific cutting force, b is the chip height (proportional to depth of cut), h is the chip width (proportional to feed rate) and z is a material constant. In the experiments the latter is calculated to determine the specific cutting force for a specific material.

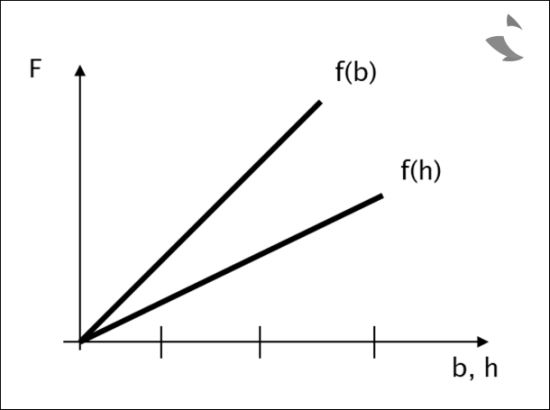

Feed rate and depth of cut

When we analyse the formula, we find that cutting forces increase faster with an increase in depth of cut than the same increase in feed. But since both are equally influential in the calculation of the chip flow rate Q (mm³/min), for optimal machine utilisation, it is best to first reduce the depth of cut or increase the feed.

Cutting speed

The missing process parameter in the cutting force formula is the cutting speed. Within a material-dependent work area, the cutting speed will indeed have no influence on the size of the cutting force. As soon as one moves out of the work area, too slowly or too quickly, other effects will occur, such as build-up of cutting edge or cutting edge disintegration, which in turn have an effect on the cutting force.

Online platform

On the 'modelgebaseerdbewerken' online platform you can consult various models and use them to optimise your machining processes. Access to the platform is free of charge, but you need to register.

You will also find the necessary explanations about working with the models on the platform, but be sure to keep an eye on the Sirris agenda because we will be organising both physical and online explanation sessions.

Would you like to know more? Then get in touch with us!

The online platform is part of the COOCK project 'Model-based processing', which was launched with support from VLAIO.