The use of (real-time) data to adjust production processes - in machining one speaks of "adaptive machining" - is the future of production. This is made possible by the increased availability of sensors. However, everything depends on having and understanding a standardised and structured model, in which the digital information is processed into a physical action. Such models are the key to successful digitalisation. In a series of blog posts, we highlight some basic models. In this fourth section, we address economic and productive cutting speed.

Everyone talks about 'Industrie 4.0' or the extensive use of (real-time) data to adjust and control production processes as the future of production. Within the machining industry, adaptive machining has been talked about for years, and thanks to the increased availability of sensors, it is now within reach. However, all this depends on having and understanding a standardised and structured model, in which the digital information is processed into a physical action. Such machining models are available and are still being supplemented by new scientific insights. In industry, however, to some extent they have fallen into disuse. As they are the key to successful digitisation, we highlight some basic models in this series of articles. In this article: the economic and productive cutting speed, two parameters that chart the choice between speed and cost.

Economical cutting speed

A previous blog covered the tool life curve, which plots the relationship between cutting speed and tool life. Both parameters are also related to cost and processing time. For example, a lower service life means that more tools are required for the same machined volume and, consequently, the tooling cost increases. On the other hand, a higher cutting speed means that the same volume will be machined faster, thus reducing machining time and machine costs. Consequently, to choose a cutting speed and corresponding tool life, there are two possible opinions: time and cost.

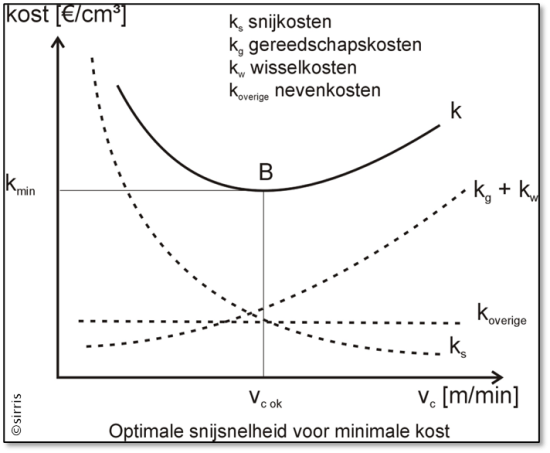

When one opts to focus on the cost, we speak of the economic cutting rate. In other words, what is the cutting speed to machine a given volume at minimum cost? To this end, three cost items need to be identified: (1) the cutting costs related to the machine, (2) the tool and change costs, and (3) the fixed costs, independent of the machining process. The first will decrease as the cutting speed increases, since less machine time is required to machine a volume. The costs related to the tool will then increase again but as a side effect also the costs related to changing tools (possibly to be minimised by using sister tools). The above graph shows in dotted line the progression of the various cost items. By summation, the curve describing the cost as a function of cutting speed is obtained where the minimum (point B) is the economic cutting speed.

Productive cutting speed

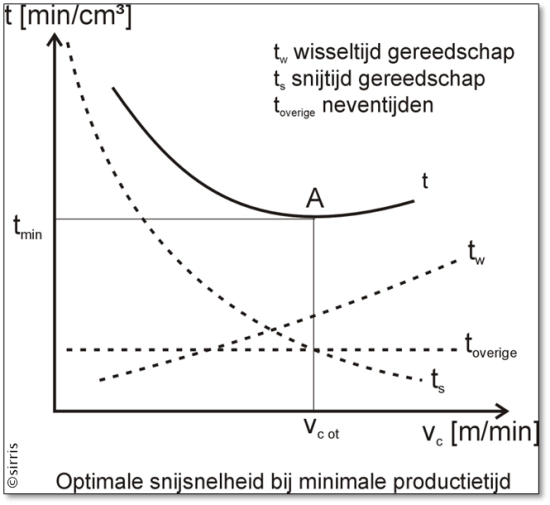

When machining time is the key issue, we are looking for the productive cutting speed, or the cutting speed at which a volume of material can be machined in the shortest possible time. Similarly, we now need to identify three cost items: (1) cutting time or machining time, (2) change time, and (3) process-independent fixed costs. The machining time will obviously decrease as the cutting speed increases. But on the other hand, tools will wear out faster and consequently more changes will have to be made.

The graph above shows the progression of the various cost items, with the summation resulting in a curve representing the total machining cost as a function of cutting speed. The minimum of this curve (point A) is the productive cutting speed.

Speed versus cost

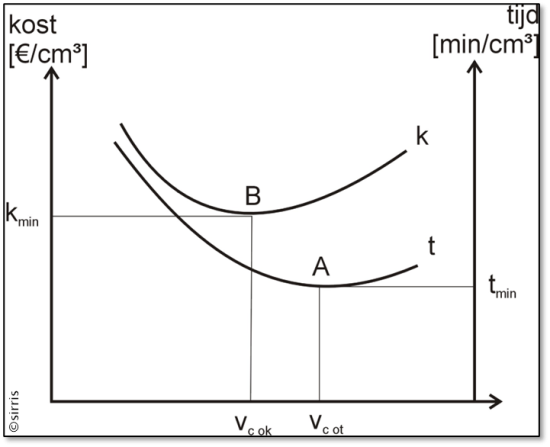

When the two curves are brought together into a graph, we find that points A and B are not identical. Specifically, the economic and productive cutting speeds are different, or in other words, the combination of 'maximum speed and minimum cost' is impossible. Thus, when choosing cutting conditions, the trade-off between time and cost must always be made.

Online platform

To support you in weighing cost versus time, you can determine the economic cutting speed for your application yourself on the online platform 'modelgebaseerdbewerken.be'. Access to the platform is free of charge, but you have to register.

On the platform you will also find the necessary explanations on how to work with the models, but be sure to keep an eye on the Sirris agenda, as we will be organising both physical and online explanatory sessions.

More information? Then please contact us!

The online platform is part of the 'Model-based processing’ COOCK project that was started with the support of VLAIO.