Cutting forces play a critical role in the milling process. Therefore, understanding the influence of cutting forces in milling and the factors that affect them is essential for optimizing the process and achieving high-quality results.

Milling is a machining process used to produce complex and precise parts from solid materials. The process involves rotating a cutting tool and moving it against the workpiece to remove material, resulting in chips. Cutting forces play a critical role in the milling process as they affect the quality of the finished product, tool wear, and machine tool performance.

Cutting forces are the forces that occur during the cutting process and are influenced by various factors, including the tool geometry, workpiece material, cutting parameters, and machine tool characteristics.

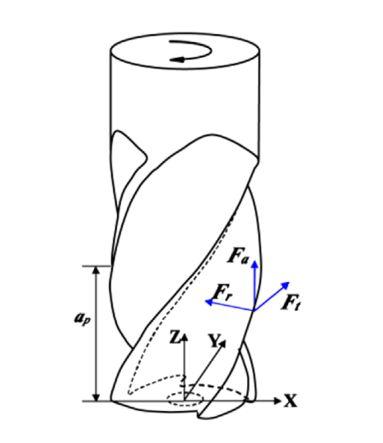

The cutting force in milling has three components: radial force (Fr), tangential force (Ft), and axial force (Fa). The radial force acts perpendicular to the cutting edge and is responsible for pushing the tool away from the workpiece. The tangential force acts parallel to the cutting edge and is responsible for shearing the material. The axial force acts along the tool axis and is responsible for the depth of cut and tool deflection.

Influencing factors

Geometry of the tool

One of the critical factors influencing the cutting force in milling is the tool geometry. The geometry of the cutting tool, such as the number of teeth, the rake angle, helix angle and the clearance angle, affects the cutting force. For instance, tools with more teeth require less power to cut, because they distribute the load evenly. Additionally, the rake angle affects the force required to cut as it influences the chip thickness, chip deformation, and the friction between the tool and the workpiece. Therefore, optimizing the tool geometry is essential for reducing cutting forces and improving the efficiency of the milling process.

Cutting parameters

The cutting parameters, such as spindle speed, feed rate and depth of cut, also affect the cutting force. Increasing the spindle speed or feed rate increases the cutting force, while increasing the depth of cut increases the radial and axial forces but decreases the tangential force. Therefore, optimizing the cutting parameters is essential for reducing cutting forces and improving the efficiency of the milling process.

Workpiece material

Another factor that affects the cutting force in milling is the workpiece material. Materials with high strength and hardness require more force to cut, leading to higher cutting forces. Additionally, the workpiece's microstructure, such as grain size and orientation, influences the cutting force. For instance, materials with smaller grain sizes require higher cutting force due to the higher strength and lower plasticity of the material.

Machine-tool design

The machine tool characteristics, such as the stiffness and damping, also affect the cutting force. Machines with high stiffness and damping require less force to cut, because they reduce vibrations and improve the stability of the cutting process. Additionally, the machine's structural design influences the cutting force, with lighter and less rigid machines requiring more force to cut than heavier and more rigid machines.

Why should you consider cutting forces and their effects during milling

Cutting forces play a critical role in the milling process and have significant effects on both the tool and the workpiece. As such, it is important to consider cutting forces and their effects during milling for several reasons:

- Tool wear: excessive cutting forces can cause tool wear and shorten tool life. This can lead to frequent tool changes, longer machining times, and increased costs.

- Surface quality: cutting forces can also affect the surface quality of the workpiece. High cutting forces can cause surface roughness, waviness, and chatter marks, which can reduce the quality of the finished part.

- Dimensional accuracy: cutting forces can also affect the dimensional accuracy of the workpiece. High cutting forces can cause workpiece deformation, which can lead to dimensional inaccuracies and part rejection.

- Machine stability: high cutting forces can also affect the stability of the milling machine. Vibrations caused by high cutting forces can reduce the machine's accuracy and increase the risk of machine failure.

- Energy consumption: cutting forces are also related to the energy consumption of the milling process. High cutting forces require higher power consumption, which can increase the operating costs of the milling process.

Considering cutting forces and their effects during milling can help optimize the machining parameters to reduce tool wear, improve surface quality and dimensional accuracy, increase machine stability, and reduce energy consumption. This can ultimately lead to improved productivity, reduced costs, and increased profitability.

Sirris online platform

On the 'modelgebaseerdbewerken' online platform you can already simulate the cutting forces for your processes. You can also access models, such as a milling economics model, and use them to optimise your machining processes. Access to the platform is free of charge, but you need to register. You will also find the necessary explanations about working with the models on the platform, but be sure to keep an eye on the Sirris agenda because we will be organising both physical and online events such as webinars and workshops.

Would you like to know more? Then get in touch with us!

Read also the 2nd part in which we discuss the estimation and optimization of cutting forces.

The online platform is part of the COOCK project 'Model-based processing', which was launched with support from VLAIO.