'Umati', the new open standard aims at unifying communication for all machine tools. This will enable user companies to rely on less fragmented solutions and to considerably reduce the commissioning time of new machines. For a machine tool manufacturer, this offers a major and quite unique sales pitch.

Adopting advanced manufacturing solutions will be considerably accelerated if they are compatible with the installed manufacturing base and if associated standards and specifications are coherent with the existing set-up. As such, standardisation is of capital importance, for the success of advanced manufacturing demands unprecedented system integration, well beyond the frontiers of specific fields, hierarchies and life cycle phases. Technical standards and specifications based on consensus, together with close collaboration with researchers, industry and SDOs (Standards Development Organisations) are the prerequisite conditions to guarantee successful results, in this field in particular.

With this aim in mind, in April 2020, VDW (German machine builders’ association) and VDMA (German federation of mechanical engineering) announced the pooling of their teams in a participative operation to define interoperability standards for the mechanical sector. The interface standard will not only enable communication between machines of different brands, but also with other in-house software solutions, such as ERP (integrated management systems) and MES (Manufacturing Execution Systems), the cloud, automation systems, etc. These interoperability standards relying on OPC UA are distributed under the umati label.

(Source : VDW)

Thanks to the many participating companies, the chances are that this will lead to the creation of a genuine standard rather than one more isolated solution. Furthermore, the choice of OPC UA for implementing the information model also contributes towards minimising risks for suppliers during system implementation, for OPC UA has already been tested and validated as a data exchange standard.

So when did umati begin?

Umati has been under development since 2017 following an initiative by VDW and 17 partners (Germany’s and Switzerland’s leading machine tool manufacturers, and leading digital control manufacturers) in collaboration with the OPC Foundation. The aim is to develop an interface that can be deployed for a range of applications such as machine and tool identification, machine and tool status monitoring, progression of a given manufacturing order, the harvesting of required data for calculating KPIs, error and alert monitoring, anticipating possible needs for human intervention to change a tool or for maintenance. On the occasion of the AMB show in Stuttgart in September 2018, the work group unveiled the first draft of its standardised semantics.

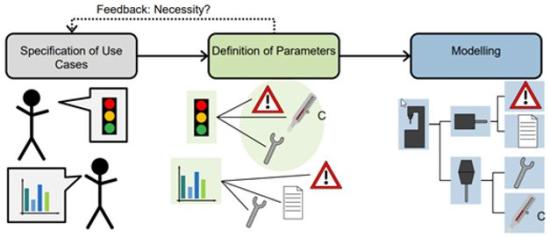

Roadmap for elaborating a standardised information model

Then in September 2019, at the EMO show in Hanover, VDW presented a functional application with 110 different machine tools connected to a total of 28 different software services. The data exchange standard used during the demonstration had been presented under the name of umati.

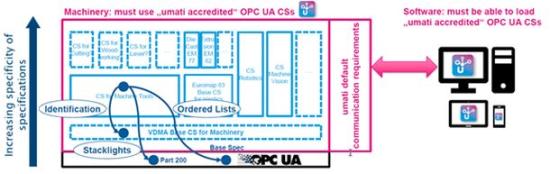

As for VDMA (German federation of mechanical engineering), it was very quick to opt for OPC UA as a data exchange standard and to draft the guide entitled Industry 4.0 Communication with OPC UA which presents solid measures to help companies to successfully introduce Industry 4.0 communication within their own production processes. Then, VDMA deemed necessary to add other specifications that rely on the former to lead to a universal interface. Since, several work groups within VDMA have been working together to distil, from the plethora of specifications that are either already published or in the making - all technologies and industries combined - a common denominator that can apply to all types of machine. And this common denominator comes in the form of OPC UA for Machinery. Under VDW’s supervision, the work group was also involved in the design of OPC UA for Machinery.

Simultaneous publication of two specifications

The first part of OPC UA for Machinery was published on the 25th of September 2020, under the specification number 40001-1, in the database supplied by VDMA. OPC UA for Machinery aims to stand as a framework standard defining the basic elements of the information model. These basic elements apply to two use cases: machine identification and localisation of all the machines in an OPC UA server.

The specification’s contents apply to any equipment that converts energy (e.g. electricity, steam, gas, human energy, pressure) into mechanical movements, heat, electric signals, pressure, etc. in order to perform a particular task in the mechanical industry. This first part will shortly be completed by a second part.

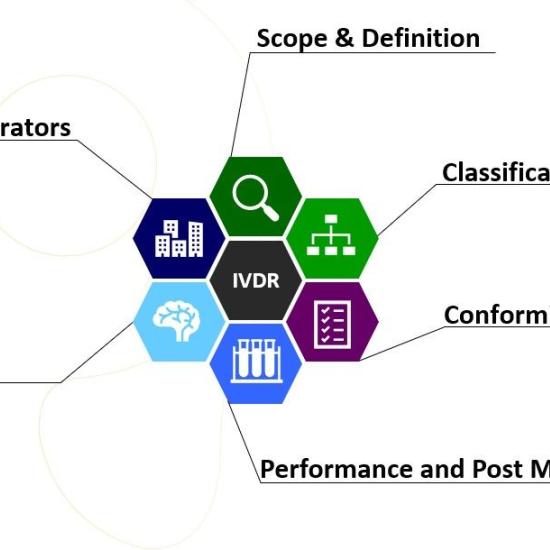

The standard, initially referred to as umati, has been renamed OPC UA for Machine Tools and published simultaneously to OPC UA for Machinery, under the specification number 40501-1. Based on the OPC UA modular concept, OPC UA for Machine Tools is the first mechanical engineering specification to totally integrate OPC UA for Machinery and the OPC 10000-200 - Part 200: Industrial Automation Model specification.

Type inheritance

(Source : umati)

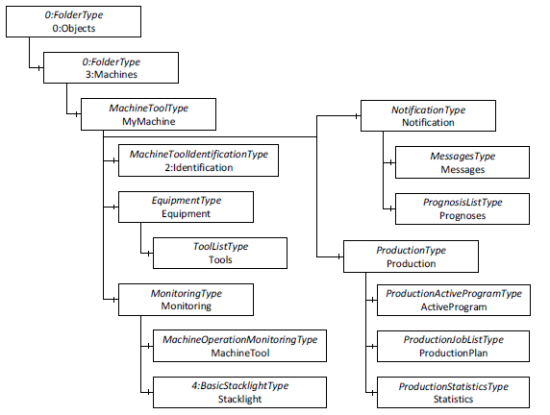

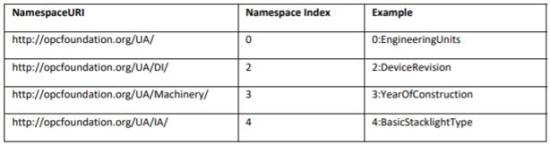

Example of an instance in the OPC UA for Machine Tools information model. This information model provides a list of 'ObjectTypes' required for modelling a machine tool interface. Certain types inherit the semantics of the parent specification.

(Source: VDMA 40501-1)

Umati, a user community

As a name, umati has been offered a new lease of life. It designates a platform for the establishment and the dissemination of the OPC UA standards that will provide a genuine plug and play environment for all types of equipment. On the 10th of November 2020, VDMA is organising an on-line event during which experts will, in turn, present OPC UA standards for mechanical engineering and a range of sub-sectors.

This article has been written within the context of the Industry 4.0 Standards Cell.

Related articles

Sources

- www.umati.org

- VDMA-Milestones for plug and play in mechanical and plant engineering 12-11-2020

- https://www.cecimo.eu/news/plug-and-play-milestones-in-mechanical-and-plant-engineering/

#industrie4.0 #norms #digital

]]>