Roadmap | Data-driven monitoring and optimisation of decentralised machining processes

In line with the shift towards Industry 4.0, where the aim is to increasingly digitalise the manufacturing process, there is a growing focus on the data-driven monitoring of machining processes. The introduction of data analytics for optimising these processes remains limited mainly to the monitoring of particular aspects of machining operations. SABCA teamed up with VUB and Sirris, in order to address the existing challenges in the ROADMAP project. This project aims to create a multimodal methodology for monitoring and optimising machining processes in decentralised manufacturing environments.

Context

The machining industry is highly competitive and extremely challenging. Upcoming regions are challenging established companies, while new machining centres and technologies are becoming available everywhere. Machining operations are very complex processes. In addition to the high degree of variability in manufacturing strategies for a particular part, there are also many possible tools, machines and settings that need to be appropriately selected. This makes it difficult to thoroughly understand and standardise the process. Together with this high degree of complexity, companies are also facing growing challenges in terms of customer demand. Customers expect them to be highly responsive, offer flexible production options and deliver the highest possible quality – all at a low cost.

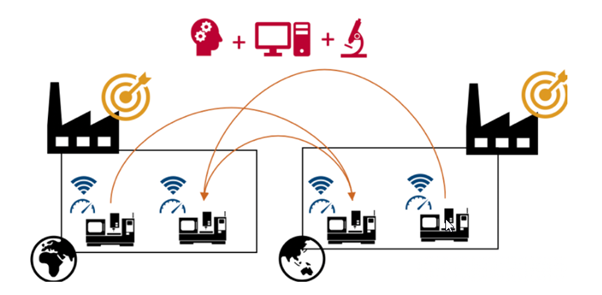

In line with the shift towards Industry 4.0, where the aim is to increasingly digitalise the manufacturing process, there is a growing focus on the data-driven monitoring of machining processes. In a decentralised manufacturing setting, companies manufacture only those products that are in demand in a specific region or country or close to regional resource suppliers. Whereas the products that are produced across these different manufacturing sites often differ, the machining processes that are undertaken to produce these products (or components thereof) are often very similar. By extracting insights from the data gathered in these decentralised manufacturing environments, knowledge can be shared between different manufacturing sites, resulting in an optimal manufacturing process that helps to meet these challenges.

However, for the time being, the introduction of data analytics for optimising these processes remains limited mainly to the monitoring of particular aspects of machining operations. In addition to the lack of data science experience and expertise in standard manufacturing companies, the main reasons for this are the lack of:

- an appropriate comprehensive measurement methodology (for both hardware and software to capture all relevant information from machining processes in the production flow, from raw material to end product)

- corresponding data-driven techniques to extract useful insights from the gathered data

- a principled approach for integrating this information with the available domain knowledge and physics-based approaches to arrive at a multimodal methodology.

Moreover, existing state-of-the-art approaches often not reliable or robust enough to be used industrially in multi-machine settings in decentralised manufacturing environments.

The aerospace sector is at the forefront of these advancements and is currently facing the aforementioned challenges, driven mainly by growing competition and more stringent customer demands. In this context, SABCA, one of the leading aerospace companies active in the design, manufacturing and assembly of structural components, teamed up with VUB and Sirris in order to address these challenges in the ROADMAP project.

Objective

The project aims to create a multimodal methodology for monitoring and optimising machining processes in decentralised manufacturing environments. This overall strategic objective can be split into the following detailed project objectives:

- The construction of a comprehensive measurement approach (HW/SW) to enable the monitoring of machining process characteristics.

- The definition of a multimodal methodology for analysing individual machining processes (multi-physics + expert knowledge + data analytics).

- The exploitation of the multi-machine environment in decentralised manufacturing environments for machining process optimisation.

- The validation of the resulting methodology both in the lab (with the Sirris Precision Manufacturing Lab) and in the field (at SABCA) by means of two industrial validation cases:

- guaranteeing product quality at a constant time

- autonomous parameter optimisation of the machining process

Presentations and publications

- Sirris presented a paper entitled "A Machine Learning-based Approach for Predicting Tool Wear in Industrial Milling Processes" at the ECML-PKDD workshop on IoT Stream for Data Driven Predictive Maintenance in Wurzburg (Germany), 16 September 2019.

- Sirris presented an extended abstract of the paper entitled "A Machine Learning-based Approach for Predicting Tool Wear in Industrial Milling Processes" at the BENELEARN/BNAIC conference in Brussels (Belgium), 6-8 November 2019.

- Sirris presented the project idea as well as an overview of the current results on tool wear prediction during the AI for Industry 4.0 Research Projects in Belgium seminar during Belgian AI Week (virtual conference), 16 March 2021.

Project partners

- Sirris

- SABCA

- VUB