Controlling and adjusting production machining through the use of data - including real-time data - is called 'adaptive processing'. It’s the future of production and is made possible by the increased availability of sensors. However, everything depends on having and understanding a standardised and structured model in which the digital information is processed into a physical action. These models are the key to successful digitisation. In a new series of blog posts, we highlight some basic models. In this first part, we will discuss the tool life curve, which is a model for finding the optimum cutting speed.

Everyone is talking about 'Industry 4.0' or the extensive use of (real-time) data to control and adjust production processes as the future of manufacturing production. Although there has been talk about 'adaptive machining’ within the field for years, this is now within reach thanks to the increased availability of sensors. However, everything depends on having - and understanding - a standardised and structured model in which the digital information is translated into a physical action. These machining models are available and are being improved by new scientific insights. In industry, however, some of them have fallen into disuse. Since they form the key to successful digitisation, we will use this series of articles to highlight some basic models. This article deals with the tool life curve, which is a model for finding the optimum cutting speed.

The Taylor formula

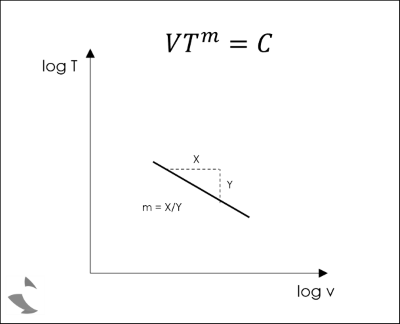

In 1907, the American mechanical engineer F.W. Taylor defined the relationship between cutting speed and tool life. 'Taylor's formula' describes what was observed empirically: a higher cutting speed gives a lower tool life. Although the formula does not take every possible factor into account, it has proven to be a good approach and forms an excellent starting point for better understanding and optimising the machining process.

The formula consists of four parts: the cutting speed (V or Vc) expressed in m/min, the tool life (T) or service life in minutes and the constants C and m, which are determined experimentally. During these experiments or tool life tests, all other process parameters, including the workpiece material, the tool, the feed rate and the depth of cut, are kept constant.

Tool life curve

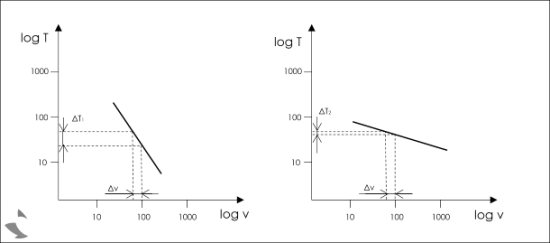

When the results of the tool life tests are plotted on a log-log scale (see figures) they form a straight line - the ‘tool life curve’. The slope of this line is a measure of the effect of the cutting speed on the tool wear. With a steep slope, a small increase or decrease in cutting speed will have a large effect on tool life. In other words, the tool is sensitive to changes in cutting speed.

As a result, the tool life curve allows the tool life (or service life) to be predicted for different cutting speeds. This information can be used in economic models to optimise the machining process according to cost or time.

Online platform

On the 'modelgebaseerdbewerken' online platform you can consult various models and use them to optimise your machining processes. Access to the platform is free of charge, but you need to register.

Would you like to know more? Then get in touch with us!

The online platform is part of the COOCK project 'Model-based processing', which was launched with support from VLAIO.