While AGVs and AMRs can bring significant benefits in terms of efficiency and productivity, they also introduce new safety risks that must be addressed. In a series of blogs, we will explore AGV safety from multiple angles. The first blog will focus on the legislative framework.

Automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) are becoming increasingly common in manufacturing, warehousing, and logistics operations. While these vehicles can bring significant benefits in terms of efficiency and productivity, they also introduce new safety risks that must be addressed. In a series of blogs, we will explore AGV safety from multiple angles, including the legislative framework that governs it, the road toward safety in terms of best practices, and the stakeholders involved and their respective responsibilities. Our comprehensive exploration of AGV safety will provide valuable insights into the challenges and opportunities associated with this rapidly developing field.

Legislative framework

The regulatory framework for AGV and AMR systems begins with the workplace directive, which establishes legal obligations for employers to ensure the safe use of products in the workplace. The Machinery Directive 2006/42/CE specifically governs the safe use of AGVs and AMRs, and requires manufacturers of machines or facilities to conduct risk assessments in accordance with the EN ISO 12100 standard. If necessary, they must take measures to reduce risks for operators. To comply with the Machinery Directive, manufacturers may utilize harmonized standards.

|

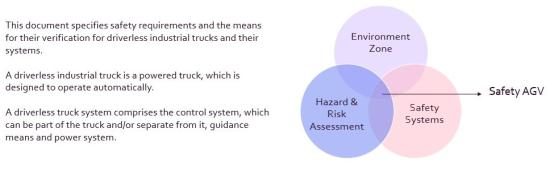

Recently, there was no C-Type standard available for AGVs and similar systems. However, due to the rapid development of emerging technologies in the field of automated vehicles, the ISO 3691-4 standard was released in 2020 to address this gap. This standard has replaced the EN 1525:1997 and refers to other common standards, such as ISO 12100, ISO 13849, and ISO 13850. It is now considered the primary international standard for AGVs and AMRs. The ISO 3691-4 outlines three critical aspects of AGV/AMR safety that must be considered for safe operation, including defining the different zones in which the truck operates and interacts with humans, identifying associated hazards and risks, and ensuring proper implementation of safety systems. A figure is provided to illustrate these aspects.

ISO 3691-4

ISO 3691-4 standard has been expanded with the introduction of EN 1175:2020, which focuses on the specific electrical aspects and automated functions of both AGV/AMR and manned industrial vehicles. These standards are not mandatory, but rather provide guidelines and standards for achieving acceptable residual risk on an automatic guided vehicle and implementing an overall safety system, including elements of design, operation, and maintenance of mobile platforms. However, it should be noted that due to the integration of AGVs and AMRs into existing systems, compliance with a single C-Type standard may not fully meet the Essential Health and Safety Requirements (EHSR) of the Machinery Directive. For this reason, 43 A and B-Type standards are referenced as supporting documents to ensure full conformity.

To conclude the first blog in this series, it is evident that the legislative framework plays a crucial role in ensuring the safe deployment and operation of AGVs/AMRs. Compliance with these regulations is not only a legal obligation, but also a moral responsibility to protect the health and safety of workers, as well as the public. However, it is essential to recognize that regulatory compliance alone cannot guarantee the complete safety of AGV systems. It is crucial to supplement compliance with best practices and risk management strategies tailored to specific operational environments.

In the next blog post, we will delve into the best practices that organizations can implement to enhance AGV safety beyond regulatory compliance.

As a company, how can you assess how to sensibly deploy AGVs or AMRs, and what are the steps involved in such a process? Contact us!

This blog post has been published in the context of the Standards Cell Industry 4.0 and the FlexIn²Log project, which aims to support manufacturing companies and their logistics and ICT partners to use digital technologies and platforms, and digitally driven AMRs, to increase the flexibility and efficiency of inbound and internal logistics.