Inspiration

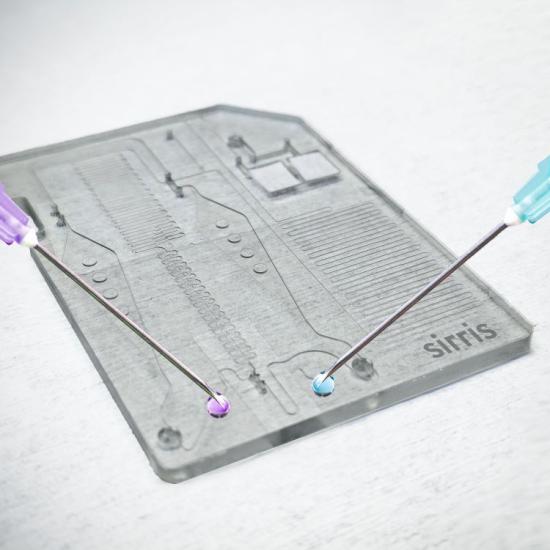

As the innovation centre for and by the technological industry, Sirris is the trusted community where forward-thinking professionals find insight and inspiration on the technology and innovations that will shape their business in the next couple of years.

Want to stay in the loop of what's moving in the tech industry?

Filter on:

Sign up for the Sirris newsletters!

Want to stay in the loop of what's moving in the tech industry?