Siemens Gamesa Renewable Energy (SGRE) is a world leader in the development and production of multi-megawatt wind turbines for use on land and at sea. The company aims to guarantee reliable and robust machines, capable of fulfilling customer expectations worldwide, even in the harshest weather conditions. To set up and perform a series of extensive cold start tests on a gearbox, a critical component of a wind turbine, the company relied on Sirris expertise and the large climatic test chamber infrastructure set up as part of the OWI-Lab project.

Guaranteed performance

The prototype for the 6-MW onshore wind turbine gearbox was subjected to a battery of climate tests at temperatures of -40 °C. The equipment performance was thus validated for use under weather conditions such as those seen in Scandinavia.

The gearbox test-bench in the climatic test chamber was used to verify the gearbox resistance to sudden shutdown followed by a restart under extremely cold conditions (cold soak test). This test set-up can also be used to validate the cold performance of the gearbox in intense heat.

At low temperatures, the gearbox may undergo changes in lubricant viscosity, which can damage other components. Rotating elements in the gearbox are at risk of insufficient lubrication or thermal expansion of subcomponents. Lubricant issues affect the flow of oil in bearings and treads. A longer cold start has a negative impact on the energy yield. Low temperatures have an effect on the materials and may cause brittleness or cracks.

The battery of tests provide Siemens Gamesa Renewable Energy with certain guarantees on gearbox performance under harsh climate conditions.

No obstacle cannot be overcome

The dimensions of the turbine component were a considerable challenge, which could be met at the large climatic test chamber at the Port of Antwerp, designed to cope with such challenges. The test facility can seamlessly respond to the onshore (and offshore) market trend to build increasingly larger (and heavier) systems and components.

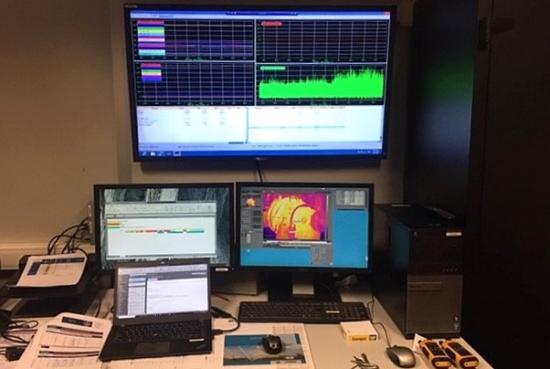

The test campaign led to another first: due to the COVID-19 crisis, the client could not travel to Belgium, but nor could they postpone the tests. The answer was to monitor the tests remotely. IP cameras and live streaming were used to resolve this challenge. Sirris took care of the set-up and ran COVID-secure test campaigns and prompt delivery to the client.