Granutools offers measuring technology to characterise metallic additive manufacturing powders. It aims to provide technology to characterise the spreadability of the powders and approached Sirris for its expertise in the field.

Powder technologies are frequently used in industrial applications of additive manufacturing. The materials used need to be accurately characterised to optimise the production process and to be kept under control. When using technologies such as selective laser sintering (SLS), selective laser machines (SLM) and electron beam melting (EBM), the resolution and quality of the spread layers making up the product depends on the particle size analysis of the powders used.

The development of characterisation techniques for the physical behaviour of bulk powders is playing catch-up to meet the state-of-the-art requirements of additive manufacturing R&D laboratories and production departments. The specific measurement processes have been automated and extensive initialisation methods are developed to achieve results that can be reproduced and interpreted. The use of image analysis technology improves the accuracy of the measurements.

Experimental research

Granutools has developed several measurement methods to meet a range of requirements for the industrial processing of powders and granulates. The GanuDrum measuring instrument can be used to automatically measure the flowability and spreadability of powders by applying image analysis to the powder in a rotating drum. Granutools asked Sirris to validate the measuring instrument.

Sirris assisted Granutools in the selection of the powders to be tested, to increase their knowledge level of the SLM procedure, to perform in-situ tests and to transfer the knowledge and know-how. Sirris provided the powders required and conducted all the experiments on their 3D printers.

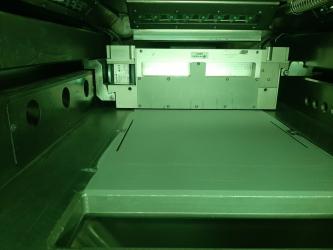

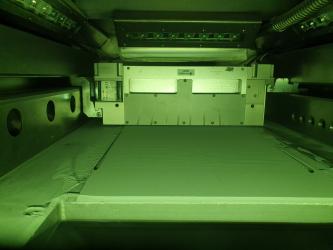

The results of the GranuDrum experiment matched those of the visual observations carried out by Sirris using their 3D printers. An image processing algorithm was applied to the observations.

| Good dispersion behaviour of powder | Poor dispersion behaviour of powder | Impossible dispersion due to behaviour powder |

Making connections

The spreadability of four metal powders was studied and compared to their behaviour in the SLM printers. Cohesion index measurements were correlated with an interface fluctuation parameter, calculated from the SLM printer images, to make a connection between the cohesion of the powders and the homogeneity of the layers obtained via the printer recoating process. The classification of powders using the GranuDrum was correlated with the homogeneity of the layers. The potential production of uniform layers using powder is thus directly related to cohesion. Characterisation using the GranuDrum therefore provides a useful classification of the powders and helps to determine the best recoating speed to improve the quality of the printing process.

The research showed that the spreadability of the powders can be monitored using these new methods. The partnership with Sirris ensured Granutools could improve their range of test equipment and assess the importance of the interaction between the powder material, the recoater and its effect on the spread powder bed in the AM machine. A connection was also made between the acquired knowledge and know-how and the quality of the spreading.