Micro is the way of the future. More and more companies are trying to miniaturize their products and enhance performance by adding micro devices and features. This approach offers plenty of benefits, including improved customization and ease of use, a lower environmental footprint, and cost reduction. To make sure you cross all the t’s and dot the i’s, Sirris shares first-hand R&D expertise and state-of-the-art equipment.

Micromanufacturing for product miniaturization

Think small for big impact

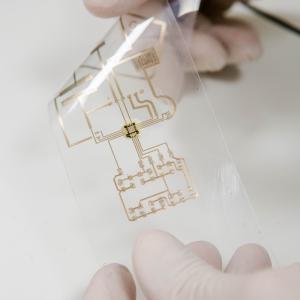

Using smaller, more precise components limits the weight and size of your products. This, in turn, has a positive effect on material sourcing, transport, storage and recycling. Moreover, micromanufacturing enables you to integrate highly reliable functionalities to products or processes that are off-limits with conventional manufacturing methods: detection, communication, automation, etc.

6 technological areas of focus

Micro-3D-printing

Micro-machining

Micro-replication

Selective micro-deposition of material

Micro-assembly

Micro-scale metrology

A gamechanger in all industries

Companies and research partners from various domains are free to leverage our R&D skills and technological resources to develop micro products:

- Medtech and healthcare (microfluidic lab-on-a-chip, microsurgery instruments, customized devices, etc.)

- Chemistry and pharmaceutics (continuous flow microreactors, etc.)

- Agriculture and food (portable devices for quality control in the field, etc.)

- Environment (tailored and miniaturized packaging of gas sensors, etc.)

- Space and aeronautics (opto-mechanical micro-components, ultra-lightweight assemblies, etc.)

- Manufacturing (integration of sensors in confined environments, etc.)

- Automotive (micro-optics, in-mold structural electronics, etc.)

- Electronics (printed electronics, plastronics, etc.)

Your experienced sidekick through the entire R&D chain of miniaturization

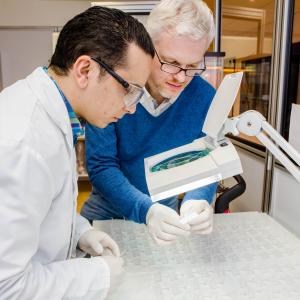

Whether you have questions on specific issues or prefer to get full guidance, our experts have your back. You’ll find them in our Micromanufacturing Lab – that’s where the magic happens. The lab boasts first-class knowhow, equipment and a unique set of enabling technologies. All for you to capitalize on.

Inspiring articles

Upcoming activities

Ready to micromanufacture your way into the future?

Denis Vandormael, manager of the Micromanufacturing Lab, will show you the ropes.