Belgium is the fourth most productive country in the world, but our productivity growth has been sputtering. In this series we present five practical tips each time to boost productivity in the office and on the shop floor.

In the first part of this series, we discussed the productivity of Belgian companies in detail. Productivity growth in our country has been substandard in recent years.

In order to support companies with their productivity improvements, we collected a lot of tips that we will publish at regular intervals. These tips are deliberately not aimed at implementing advanced technologies, but at improvements that can be achieved with relatively little effort.

Tip 31: Improve ergonomics, provide lifting and transport aids

A few years ago we were invited to visit Scania in Zwolle for a guided tour. Our host surprised us with a special announcement at the start of the tour: “We do everything we can to make the work easy for our workforce. After all, we don’t want people to be tired by the end of the shift, so that they still have enough energy to go to the gym. So if you see someone with a drop of sweat on his forehead, let us know, it means he is sick and we have to send him to the doctor.” This work philosophy surprised some visitors, but it does work. Scania has not had a single year of losses since 1934.

Ergonomically designed workstations make the work less tiring, making the employee more productive. Such workplaces also reduce health problems, reduce absenteeism and enable people to continue working for longer. Lifting and moving materials is the main cause of avoidable physical injuries (mainly low back pain) and therefore requires special attention. Many improvements can often be made with simple means, such as lifting and transport aids.

Studies show that ergonomic improvements typically pay for themselves in less than one year.

Van Hoecke, manufacturer of furniture fittings and Factory of the Future, takes the ergonomics of its employees seriously and has made numerous improvements at its factory in Sint-Niklaas (see photo below).

A simple trolley improves ergonomics

(Source: Van Hoecke)

Besides simple solutions such as the use of trolleys and height-adjustable work tables, there are many specialised lifting aids. An example of a lifting aid can be found in the video below.

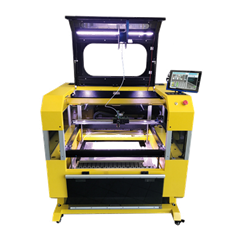

Tip 32: Consider 3D printing of parts

Many parts are still manufactured using traditional production processes (such as laser cutting, bending, turning, milling, etc.). Although these production processes are fast, they have some fundamental drawbacks. Many parts often require several production steps, which results in a lot of logistic operations (scheduling of orders, supply of material, transport between steps, intermediate storage, ...) and long lead times. The traditional machines are also typically very capital-intensive and the changeover times are often long.

We recently saw a West-Flemish machine builder who opted for a radically different approach by choosing to print part of its required metal parts in 3D plastic from now on. The company purchased about ten 3D printers for this purpose. After all, a large proportion of the parts are not load-bearing and can therefore just as easily be made of plastic. 3D printing is a relatively slow process, but due to the very low cost of 3D printers (a few hundreds of euros) a considerable amount of printing capacity can be achieved with a limited investment. Printing can also take place largely unmanned, which greatly improves labour productivity.

Tip 33: Hold stand-up meetings

Meetings are one of the main sources of wasting time at offices. Meetings often start too late, miss rhythm and take longer than necessary. However, a good meeting can avoid time wasted as a result of misunderstandings or a series of back and forth e-mails.

A simple way to greatly reduce meeting time is to hold stand-up meetings, where the participants no longer sit down comfortably, but are simply standing. A number of higher tables can help to easily write things down and consult documentation.

Stand-up meetings not only improve the meeting culture, but are in themselves much healthier for office workers. Prolonged sitting is associated with many illnesses, such as diabetes, vascular disease, depression and even premature death.

Tip 34: Reduce the changeover time

Machine changeover is a secondary process that typically receives insufficient attention. As a result, it is usually relatively easy to reduce the changeover time by approx. 30%. The first step in improving the changeover time is to improve the organisational aspects. Make sure that all information, materials, tools, ... are available before the actual start of the changeover. Once the organisation is well under control, you can also start thinking about more technical interventions.

A good starting point for improving the changeover is to make a video recording which you then analyse with the whole team. The methodology for reducing changeover times is SMED ('Single Minute Exchange of Dies'). There are many training courses that you can follow for this purpose. Short changeover times also allow production with smaller lot sizes. This shortens the turnaround time and thus increases delivery reliability. As a result, following up late orders requires less work.

Do you have any tips to share? Let us know so that we can share them and become more productive together! The best tipster gets a nice gift!

Shortening lead times makes it possible to grow as a company and to reduce lots of indirect costs. The quick response manufacturing (QRM) production strategy makes this possible for companies in a high-mix, low-volume environment. From 19 January (Genk) and 4 March (Ghent) we organise a next QRM training cycle (in Dutch). More information is available in our agenda!

Click here for an overview of the other parts in the series.