Microfluidics in industry

Polymer-based microfluidic chip production is ideally suited for high-volume, low-cost applications such as bedside diagnostics, quality control in the field and rapid sample preparation for analysis. A range of different techniques are used that make it possible to produce microscopic patterns on macroscopic parts, which is a characteristic of microfluidics. Some techniques are mostly used in research and development (R&D), while others are perfectly suited for industrial-scale production.

1) Soft lithography

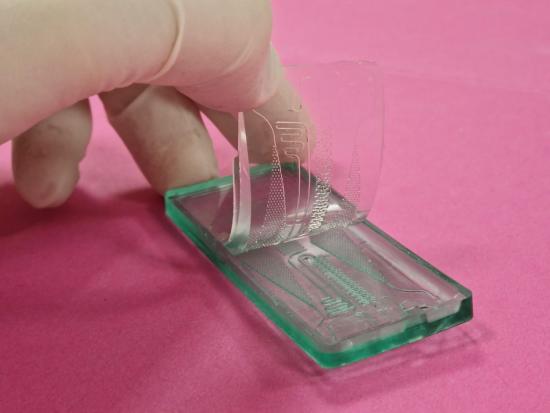

Soft lithography in combination with casting a thermochemically-curing polydimethylsiloxane (PDMS) elastomer is a particularly well-proven technique in academic R&D. This allows the creation of flexible replicas that can be used either as parts or as moulds for reproducing microscale patterns in liquid materials as these are curing. This method adds great flexibility to the rapid prototyping of complex designs.

2) Stacking and laminating pre-cut polymer films

Stacking and laminating pre-cut polymer films (by laser, milling or robotic cutting) is also a fast and simple prototyping technique that can be used in R&D to produce thin and/or flexible microfluidic systems.

3) 3D printing

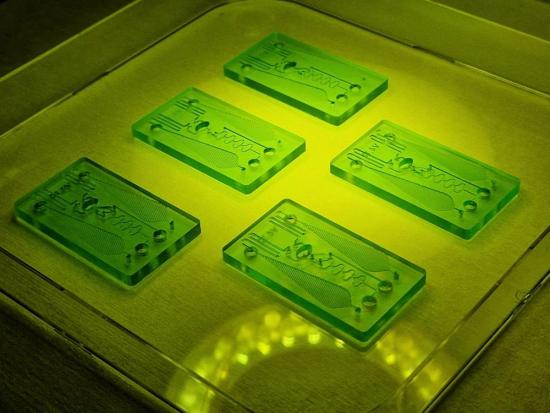

3D printing - and, more specifically, micro-stereolithography and multiphoton polymerisation techniques - have recently proven particularly versatile in the production of microfluidic systems. They offer exceptional flexibility and enable the rapid creation of complex 3D structures via selective exposure of a photopolymer resin in successive layers. Although the technique is mainly used in R&D, it can also be used for the industrial production of small series and even the production of one-off pieces with a very high degree of customisation.

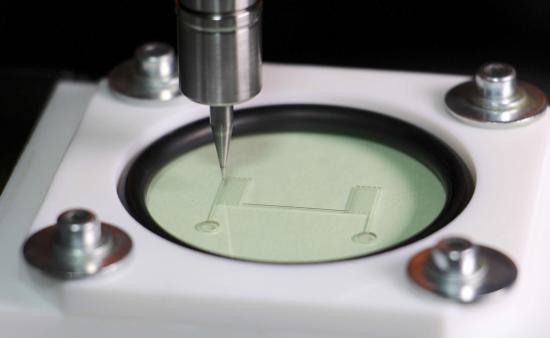

4) CNC micro-milling and laser micro-machining

Direct machining by CNC micro-milling is a technique that allows microfluidic systems to be created directly and with extreme precision by removing material with micro-tools. Laser micro-machining does the same but with pulsed energy beams. These techniques, which can be extended to materials other than polymers (such as metal or glass), are particularly well suited to applications where very close tolerances are essential. They can be used in R&D as well as in small production runs.

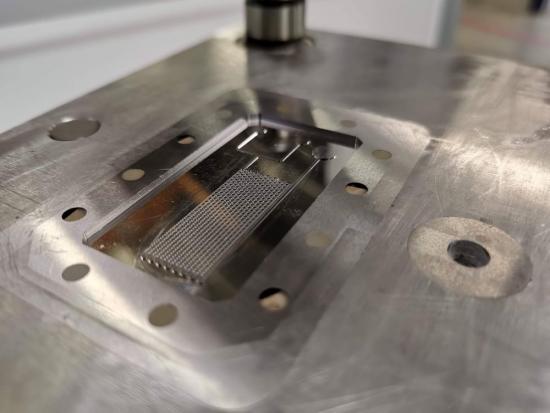

5) Micro-embossing

Micro-embossing, both isothermal and non-isothermal, offers a production method for microfluidic structures on a larger scale, both in size and quantity. In this technique, a polymer is thermoplastically deformed using a heated stamp to create microscopic structures. Micro-embossing is also suitable for small-scale production.

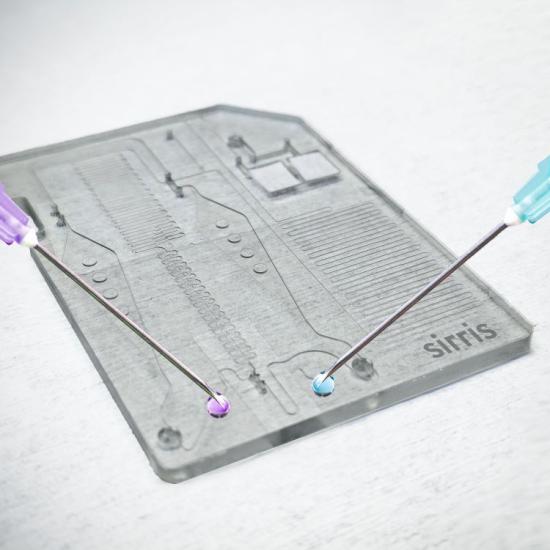

6) Injection moulding

Injection moulding involves injecting molten polymer into moulds to quickly and efficiently create microscopically precise structures. This technique, which is compatible with a wide range of thermoplastics, is an important way of producing microfluidic systems in high volumes and at low cost.

This process can use transparent materials such as COC, COP, PC, PMMA and PS as well as engineering thermoplastics such as PEEK and even more recent materials that are of biological origin and/or biodegradable (PLA). There are also thermoplastic elastomers (TPE), which are flexible. The use of auxiliary systems such as Variotherm® can increase injection moulding precision by optimising the thermal conditions of the mould.

7) Ultrasonic replicating

Ultrasonic replication is another plastic injection technique. It is distinguished by its ability to produce the kind of very fine details that are usually not possible with conventional injection moulding. In this method, the polymer is fluidised with the aid of ultrasound. This method is ideal for applications that require high resolution, although it is limited to the production of small parts.

8) Roll-2-roll

Finally, there is roll-2-roll, which is a technique that lends itself to very large-scale production of flexible and thin parts. It is a continuous stamping process using microstructured rolls.

Stamps or dies required

These replication techniques require the production of punches or dies by direct micromachining (micro-milling, laser machining, electroerosion, etc.) or indirect micromachining (for example by electroforming nickel from an original pattern created by photolithography).

Sealing

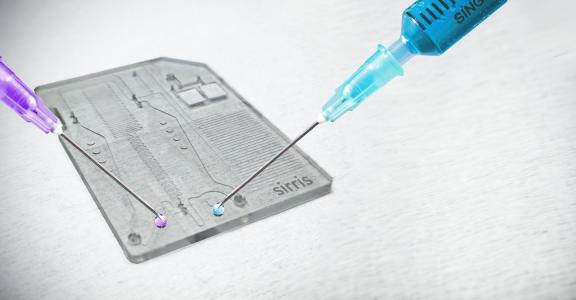

All the above methods can be used to create macroscopic parts with microfluidic channels on their surfaces. To obtain a fully functional part, it is necessary to seal the part with a lid or film. The adhesion of this lid or film is crucial.

The methods used depend on the specific requirements of the application and include such techniques as gluing, thermal and/or solvent-based sealing, and laminating. The lid or film thus creates a hermetic seal on the microfluidic chip, making it suitable for use in the given scientific, medical or industrial context.

Would you like to know more?Most of the production techniques described in this article are available from Sirris for creating your pre-industrial microfluidic prototypes. Meet us at our booth 73 on the Knowledge for Growth event in Antwerp on 15 and 16 of May Come to our seminar 'Supplying the life sciences industry: a fast-growing market' on 23 May Contact us for more information

|