Trinity | AMR Logistics Orchestration For Agile Production

The Trinity project is at the crossroad of robotization/automation, digitisation and logistics optimisation. It focuses on digital technologies and advanced robotics for agile production in future European manufacturing ecosystems.

Context

The shift from mass production to the production of more complex customized products with higher added-value in ever smaller batches and with ever smaller lead-times, results in an increased complexity in production. In order to survive, especially in high-wage regions, this complexity needs to be managed and, consequently, production systems need to become smarter and more agile. Recent studies and inquiries clearly indicate that, besides flexible automation of the production processes, optimization of internal production logistics is crucial in becoming more agile. It can indeed be observed that the way that the internal production logistics are currently organised are the bottleneck for becoming more flexible.

The trend to ever smaller batches with ever smaller lead-times results in increasing complexity in manufacturing. More and more, the current flexible production systems must be complemented by digitization and automation of internal logistic processes to achieve the necessary agility in production. Fortunately, recent technological developments within the field of autonomous mobile robots (AMRs - the recent name for 'automated guided vehicles' or AGVs) offer opportunities to flexibly automate internal logistics operations at an affordable/acceptable cost. However, different specific logistic challenges first need to be solved to assure a broader implementation of those technologies in the EU manufacturing industry. Although AMRs allow logistic automation, the control of the tasks to be performed is too complex, loading and unloading is too slow (docking), the AMR is only a basic platform without automated handling solutions and it is difficult to combine systems of different brands. As a result, the ROI is unclear, preventing implementations at SMEs.

This project aims to tackle some of the challenges by constructing a prototype and implementing and testing it on an industrial use-case at Altachem (development of a proof-of-concept demonstrator).

Approach

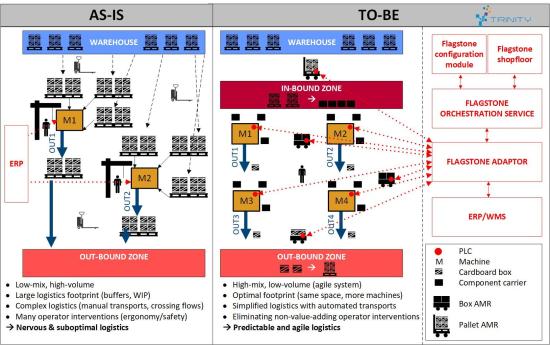

Within the Trinity project Sirris, Flagstone and Altachem will demonstrate both technological and economic feasibility of implementing AMRs on SME shop floors for the flexible production of smaller series (EU SME challenge). Flagstone will develop software tools that allow event-driven orchestration of AMRs, driven by ERP/WMS, PLC and operator input. A modular structure will enable to easily extend new orchestration implementations and hardware of other brands.

Sirris will develop the necessary automation add-ons to allow easy docking, loading and unloading of AMRs. These prototype solutions will be implemented and tested in a demonstrator at Altachem.

This will demonstrate following benefits:

- logistic AMR-driven concepts for reducing the storage of WIP from the shop floor,

- AMR orchestration driven by ERP/WMS,

- how operators remain in control of an automated system,

- autonomous quick and flexible transport, docking, loading and unloading,

- hardware agnostic implementation eases integration with existing technology and equipment from different brands.

Together, these integrated soft- and hardware tools will demonstrate the possibilities of AMRs to respond to the needs of an agile production at European SMEs.

Objective

The above demonstrated benefits provide the basis for sound future business plans. Broad dissemination of the demonstrator supports Sirris in its mission to accelerate the spread of new AMR technology for future flexible logistic concepts. These digital components would also be applicable on other European SMEs, so they can have the same benefit of becoming a digitally supported agile organisation.

Target group

SMEs who want to achieve a flexible production of smaller series.

Reference

Trinity AMR Logistics Orchestration for agile production

Project partners

- Sirris

- Flagstone (project leader)

- Altachem