New step in overcoming the lack of interoperability and standardisation

The Industrial Internet of Things (IIoT) and Industry 4.0 are transforming the way we connect, monitor, and control industrial systems and devices. However, one of the biggest challenges in this domain is the lack of interoperability and standardisation among different protocols, data formats and platforms. This leads to data silos, inefficiencies and increased complexity. To overcome this challenge, a new concept called Unified Namespace (UNS) has emerged as an interesting next step in the standardisation of IIoT and Industry 4.0.

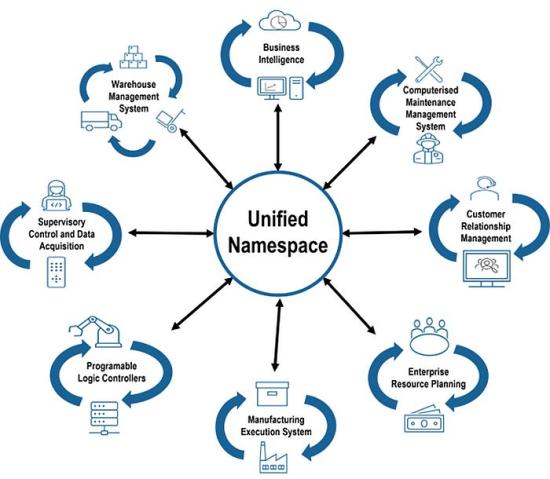

UNS is a logical abstraction layer that provides a unified collection of all data sources and destinations in an industrial system, regardless of their underlying protocols or formats. UNS enables seamless data exchange, integration and analysis across different devices, applications and platforms.

The term "Unified Namespace" was coined around 2015 by Walker Reynolds, the founder and CEO of Intellic Integration. He defined it as "a hierarchical naming scheme that provides a unique and unambiguous identifier for every object in a system.

What problem does the UNS solve?

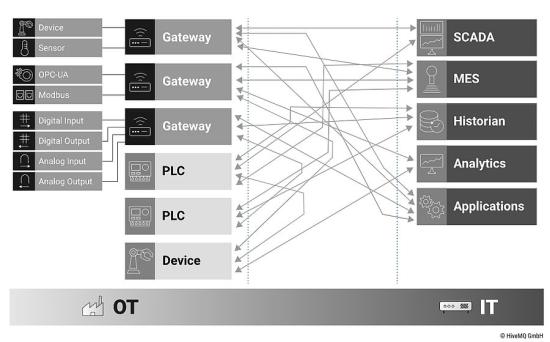

Industry 3.0 was characterised by the automation of industrial processes using computers and networks. However, this also led to the proliferation of many point-to-point connections between different devices and applications, such as sensors, actuators, PLCs, SCADA systems, ERP & MES systems, etc.

This way of working had several disadvantages, such as:

- Lack of interoperability: different devices and applications used different protocols, data formats and platforms, making it difficult to exchange data between them.

- High complexity: each point-to-point connection required custom integration, configuration and maintenance, increasing the complexity and cost of the system.

- Low scalability: each point-to-point connection had a limited bandwidth and reliability, limiting the amount of data and devices that could be handled by the system.

- Poor flexibility: each point-to-point connection was fixed and rigid, making it hard to add, remove or modify data sources and destinations in the system.

- Low efficiency: each point-to-point connection involved redundant data transfers, conversions and validations, wasting network resources and computing power.

- Low security: each point-to-point connection exposed data to potential eavesdropping, tampering or unauthorised access.

All this resulted in the famous Industry 3.0 spaghetti architecture.

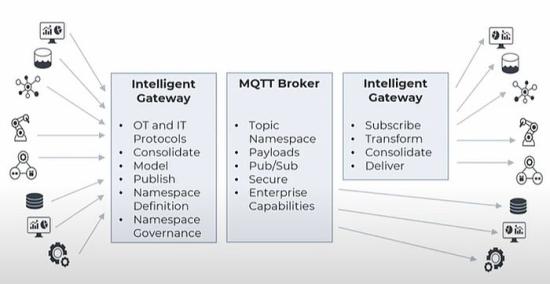

Industry 4.0 aims to overcome these disadvantages by using a central broker-based solution for data communication. A broker is a software component that acts as a mediator between different devices, applications and services. A broker supports multiple data formats. It also maintains a hierarchical namespace that maps all data sources and destinations to logical names and topics.

This way of working has several advantages, such as:

- Interoperability: a broker enables seamless data exchange between different protocols, data formats and platforms, without requiring any changes to the existing devices or applications.

- Simplicity: a broker reduces the complexity of data communication by providing a unified view of all data sources and destinations in the system.

- Scalability: a broker supports horizontal and vertical scaling of the infrastructure to handle large volumes of data and devices in the system.

- Flexibility: a broker allows dynamic addition, removal and modification of data sources and destinations in the system, without affecting the existing data flows.

- Efficiency: a broker improves the efficiency of data communication by eliminating redundant data transfers, conversions and validations.

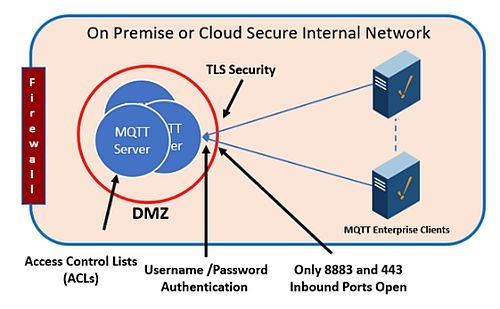

- Security: a broker provides end-to-end encryption, authentication, authorisation and access control for all data communication in the system.

Working with a central broker-based architecture leads to fully integrated data flows all around your company. Data flows are also not limited to typical shop floor systems, but could easily work together with typical higher level data flows such as ERP and MES. This fully integrated data flow is in the following graphic.

Such architecture can be started for new projects, while your legacy integrations can be changed over one by one. This way, the UNS can become the backbone for your digital transformation, offering the potential to evolve and adapt as your organization embraces new opportunities and technologies.

How does the UNS work?

The UNS works by using a broker-based architecture that acts as a central hub for all data communication in an industrial system.

The UNS is a hierarchical data structure that provides a consistent way to organise and name data in an industrial IoT (IIoT) system. It is a way to create a single version of the truth for all of your data, regardless of where it comes from or where it is stored.

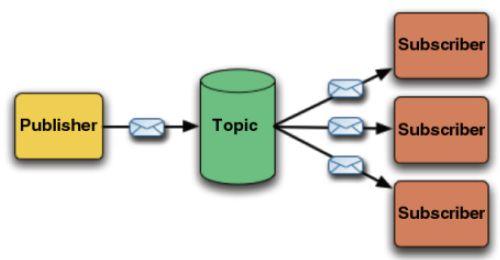

The UNS is based on the MQTT protocol, which is a lightweight, publish/subscribe-messaging protocol that decouples the data producers (publishers) from the data consumers (subscribers). Publishers and subscribers do not communicate directly with each other, but use a broker as a central communication point. A broker supports multiple topics. Each topic is a unique identifier that represents a specific flow of data.

The UNS is typically divided into three levels:

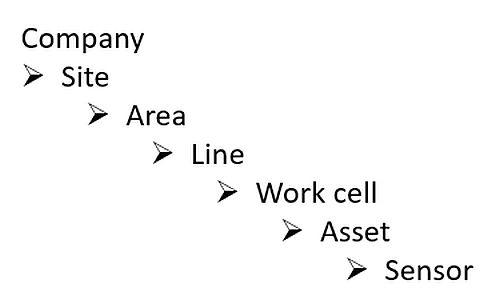

- Root level: this level identifies the overall system or plant.

- Middle level: this level identifies the different subsystems or areas within the system.

- Leaf level: this level identifies individual objects within the system, such as sensors, actuators, machines, and products.

The standard ISA-95 part B is typically used for the organisation of the topic structure. It looks like enterprise/site/area/production line/work cell/sensor name.

In an MQTT broker, data (payload) can take various forms, ranging from binary to text-based. Text-based data, often formatted as JSON, offers distinct advantages as it can easily be parsed by both algorithms and humans, facilitating efficient data processing and simplifying debugging processes.

In achieving genuine digital transformation, manufacturers must prioritise retaining control and ownership of their data, a crucial facet that can only be ensured through the adoption of open systems. The UNS implemented with an MQTT broker serves as a pivotal enabler in this pursuit, empowering manufacturers to maintain sovereignty over their data, while fostering seamless communication and interoperability, ultimately facilitating a successful journey towards true digital transformation.

Minimal technical requirements for the UNS

- Open Architecture: MQTT specifications are publicly available for implementation. As such, many organizations have adopted these specifications, making it easy to swap or add components from different IIoT vendors into the UNS data ecosystem.

- Light weight: the creators of MQTT originally built it to monitor oil pipelines over satellite; so they designed it to have minimum overhead to fulfil the bandwidth-efficient and reliability requirements. Additionally, MQTT uses a binary protocol, which significantly reduces the overhead on the wire.

- Report by Exception: MQTT Sparkplug’s Report by Exception rule ensures that data producers publish data to the UNS only when they detect changes in the monitored value. Reporting changes only enables the UNS to maintain the current state of its architectural components without continuously polling the data sources to establish a current state.

- Edge Driven: data is pushed into the UNS (MQTT Broker) by nodes at the edge of the network as a single source of truth as opposed to collecting modelled machine data from different intermediary sources.

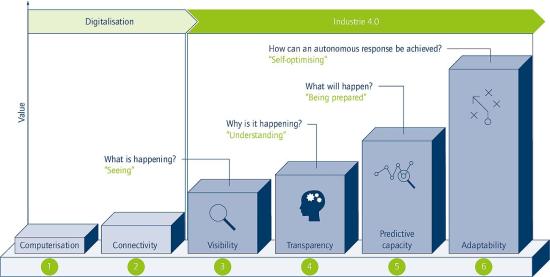

Digital transformation, Industry 4.0 and the UNS

Digital transformation is an ongoing journey that spans several years. It begins with the critical steps of connecting, collecting, storing, reporting and visualising vast amounts of data and information. Subsequently, machine learning and artificial intelligence are employed to find valuable patterns and make predictions to solve future issues easier and faster.

For a robust digital transformation framework, the UNS serves as an ideal backbone. Sensors publish their values and state changes to the broker, while time series or relational databases subscribe to relevant topics for storage. Dashboards display real-time data for operators to monitor machinery and shopfloor activities. Simultaneously, this data is published to a cloud broker, where it resides in data lakes for in-depth analysis using machine learning and AI algorithms.

Sirris and the UNS

In 2019, Sirris established a demonstration factory known as "Made Real," where the UNS principle served as the digital backbone for seamless integration. This innovative project hinged on the central MQTT broker, enabling all systems to communicate effectively. Through this endeavour, Sirris gained invaluable firsthand experience in implementing and operating architectures that leverage UNS principles, contributing to their expertise in advanced manufacturing solutions.

Discover our pilot factory 4.0 Made Real by Sirris here: https://youtu.be/mEUM8g0k4gU

The UNS in industry

As a company, leveraging the benefits of UNS is not only feasible but highly advantageous. There is no inherent limitation preventing the adaptation of UNS, and it offers immense flexibility in architectural configurations. Machine and sensor data collection can seamlessly integrate with UNS, with a timeseries database effortlessly subscribing to the relevant topics, simplifying data storage without extensive integration. This stored data becomes easily accessible through various dashboards, enabling operators to monitor different KPIs. Moreover, the data can be analysed to uncover valuable insights, and machine learning models can be trained, providing operators with tools to optimise machine efficiency and enhance operations, ultimately revolutionising the capabilities of the industry.

How to get started with the UNS?

Embarking on your journey with the UNS is straightforward. To get started, consider following the AI-Pathfinder project or Walhub project (digital coaching/IOT), or reaching out to Sirris experts, who can provide valuable insights into practical implementation options. Setting up a proof of concept is a viable approach to showcase the potential benefits.

Additionally, Sirris offers expertise and support for your UNS implementations and architectural endeavours, ensuring a smooth and successful integration into your operations.

In collaboration with Flanders' Food, we offer a webinar on AI and Data for machine builders in the food industry on 01 March 2024 from 12h00 - 13h00. More information on the agenda of Flanders' Food. We will share expertise on smart machines, sensors and data treatment techniques.

Sources

https://www.hivemq.com/blog/sparkplug-essentials-part-2-architecture/

https://cirrus-link.com/mqtt-security-best-practices/

https://op-tec.co.uk/knowledge/unified-namespace

https://www.researchgate.net/figure/Publish-Subscriber-messaging-3_fig1_309040827

https://www.isa.org/intech-home/2017/november-december/features/isa-95-to-support-smart-manufacturing-iiot

https://www.highbyte.com/blog/is-highbyte-intelligence-hub-a-unified-namespace

https://maxbyte.co/industry-4-0-transformation-roadmap-is-important-for-every-organization/