The roles of buffers

To make your planning system robust, you use different types of buffers. What are they used for? How do they work? This article introduces some basic concepts, which will be explored in detail in our next workshop on planning system.

If you have worked in the supply chain, you are aware that daily operations come with unexpected challenges: machinery malfunctions, components run out of stock, suppliers face delays, urgent orders arrive, batches encounter quality issues, and key operators may fall ill – sometimes all at once. Does this sound familiar?

Despite efforts to minimise variability, it is a constant presence. To maintain the smooth flow of operations and quickly adapt to market changes, we must integrate buffers or shock absorbers into our system to absorb some of the variability.

Three crucial tactics for better buffer management

There are three ways to dampen variability:

- We can use stock. By storing extra inventory in warehouses or in-store locations, a buffer is created to address sudden demand. This approach is straightforward to implement and works well for items with recurring demand that are suitable for storage.

- We can insert safety time. In other words, organising queues in our flows.This is particularly effective for order-based processes where items are non-recurring and cannot be stocked. Allowing time as a buffer helps manage variability.

- We can have available capacity. If certain process stages have excess capacity, it becomes possible to absorb demand peaks or compensate for delays due to unforeseen events. This might entail implementing flexible production schedules, cross-training workers, and adopting technologies that enable rapid adjustments in production volume.

These three types of buffer complement each other and 'work together' to establish a robust model: if you have excess capacity you need less stock and can reduce your downstream queues.

Which of these three buffers really has the most potential?

When you invest in stock, you are making decisions well in advance of knowing your actual orders. Even with a well-designed model with strategic decoupling stocks and a delayed differentiation approach, there's still a risk of not having the right stock and not meeting demand as expected.

If you introduce time buffers in your industrial flow, it means setting response times, limiting your ability to adjust and respond quickly to market changes.

On the other hand, having available capacity, both for you and your suppliers, allows for adaptability to various demand scenarios.

Among the three types of buffers, capacity stands out with the most potential and flexibility.

Don't suffer: position and size to protect the flow

The initial step in establishing buffers involves a design phase: thoroughly describing and analysing the flow within the industrial system from start to finish. During this process, decisions are made regarding the placement, size, and management of stock, time, and capacity buffers. These decisions constitute investments aimed at constructing a supply chain that is both agile and resilient, recognizing that each buffer costs. (see table below).

| Buffer type | Stock | Time | Capacity | |

| What is waiting? | Material | Customer | Resources | |

| Which costs? | Stock cost | Lost orders and additional overheads | Spare capacity | |

| When using it? | Normal demand, popular items | Abnormal demand (large order volumes) | Normal demand; custom-made items |

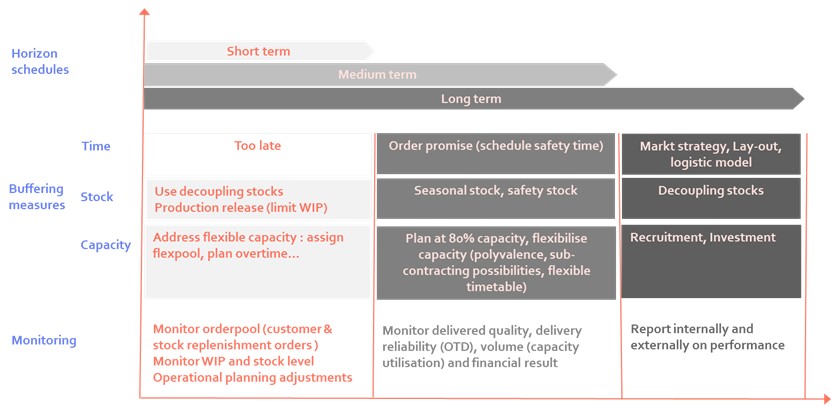

The placement of buffers is crucial to get a robust planning system: we position stock, time and capacity buffers at just a few strategic points, which will enable priorities to be managed. We can place buffers at three planning levels, as indicated in the following figure.

At the highest level, long-term production planning involves organizing the factory floor, positioning decoupling stocks, and an aggregate production plan aligned with strategic goals. It spans a timeframe longer than the delivery time of new capacity investments.

The lowest level, short-term production planning, determines when specific production steps start, controlling the material flow on the shop floor by assigning tasks to specific capacities (cells, machines, or workers).

The intermediate decision level aligns high and low-level decisions, translating and adjusting high-level choices into inputs for short-term production control. This planning spans a period longer than the longest production lead time, allowing for effective capacity expansion reactions (additional shifts, outsourcing ).

Determining the size of buffers is also an important component of buffer management. Managers at the plant must strike a balance between having excessive or insufficient buffers. Excessive buffers can result in wastage, inefficiency, and complacency, while inadequate buffers may lead to missed deadlines, customer dissatisfaction, and increased stress. The sizing of buffers takes into account various factors, including anticipated variability or uncertainty, the target service level or performance measure, the cost and availability of resources, and the feedback and control mechanisms in place.

Using buffers to take action

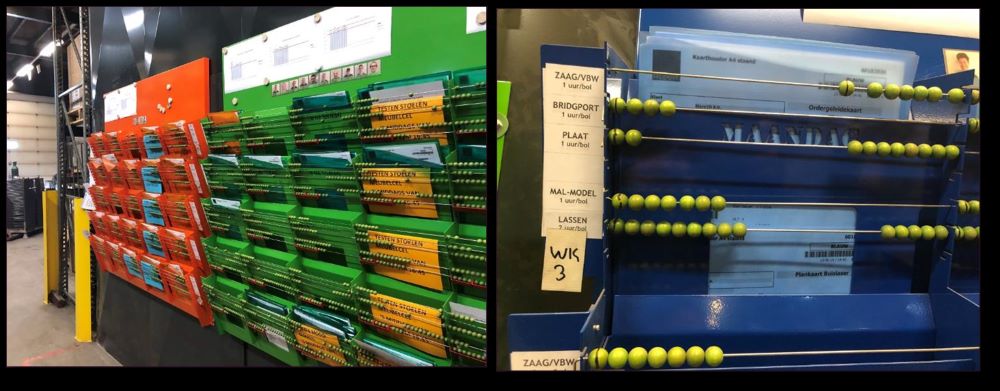

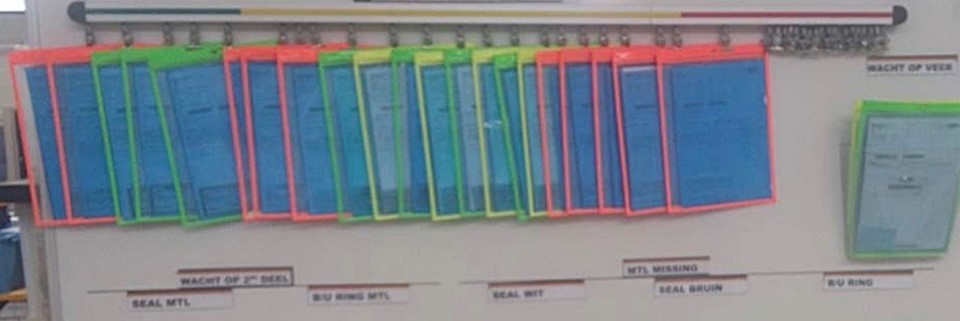

buffer will trigger decisions by our teams on a daily basis. To do this, whether it is a question of stock, time or capacity, we set up a visual management system to give our teams the signals they need to take action: place an order, speed up an order in progress, add staff to a workstation, slow down to avoid clogging up a queue, and so on. This visualisation enables a shared understanding of priorities, and decision-making that promotes the rapid and reliable flow of traffic.

Workshop: Setting up an efficient planning system

This blog highlights the fact that the right stock, the right time, the right available capacity are investments that ensure the focus is on the flow and therefore on the value delivered to customers!

Would you like to learn other facets of an efficient planning system for high-mix-low-volume production company ? Join our quick response manufacturing experts for our workshop ‘Setting up an effective planning system’ at A6K Charleroi on 15 February 2024 and let them guide you. Don't forget to register!