SAMUEL | Smart additive manufacturing - an AM intelligent platform

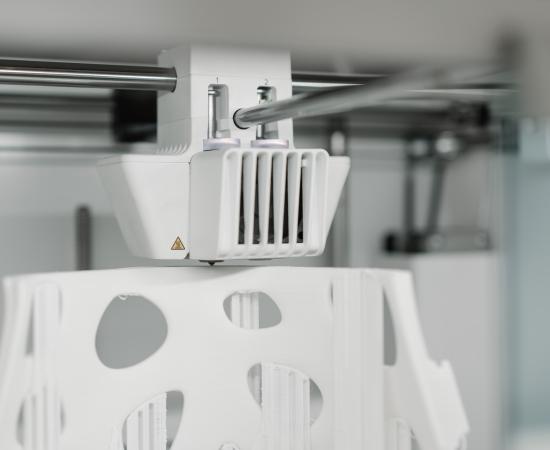

As the use of the additive manufacturing (AM) technologies is growing, so are the expectations. AM processes must be significantly improved if they are to meet these higher expectations. The SAMUEL project aims to improve the AM processes, workflow and machine learning methods.

Context

Additive manufacturing (AM) is seeing increasingly mainstream use for prototyping, tooling and production. Many industries are showing a growing interest in 3D-printed parts, pushing expectations towards certified manufacturing where the final parts are of higher quality, while small-series manufacturing is pushing expectations towards lower-cost additive manufacturing. AM processes must be significantly improved if they are to meet these higher expectations. Any major improvements will require the application of new techniques, such as artificial intelligence and, more specifically, machine learning for 3D-printing data collected over the last 25+ years.

Objective

The major goals of the SAMUEL project are to:

- improve AM processes: improve the quality of printed parts and/or reduce the cost of manufacturing.

- improve the AM workflow: increase automation and improve the repeatability of steps in the workflow and extend the knowledge of AM processes, resulting in a higher AM adoption rate by lowering the threshold for users.

- improve machine learning (ML) methods for use in AM (and in manufacturing industry in general): extend the applicability of ML to a) complex and rich real-world industrial datasets, consisting of heterogeneous data types (e.g. large volumes of sensor data, images, detailed digital representations of 3D objects), and b) the AM-specific processes in an industrial environment.

Approach

The major innovation of the SAMUEL project will be a unique set of tools and processes allowing various types of users, such as designers, process engineers and supply chain experts, to identify, understand and validate suitable design rules, adequate materials, equipment, manufacturers, process parameters, etc. in order to ensure compliance with design constraints through in-process validation at the end of the manufacturing process.

The toolset will consist of innovative data mining and machine learning modules which take into account feedback from printed 3D parts, new material definitions, equipment parameters, etc.

The tools, processes, modules and techniques developed via the SAMUEL project will be tested and demonstrated in four to five use cases provided by the project partners.

Reference

ITEA-4 17010 Samuel - Smart Additive Manufacturing– an AM Intelligent Platform

Project partners

SAMUEL is an ITEA4 project with three partners from Belgium and five partners from Canada.

- ITEA-4

- 3DPartFinder

- CRIQ

- Cr3do

- FusiA Groupe

- FZ engineering

- Materialise

- Tekna