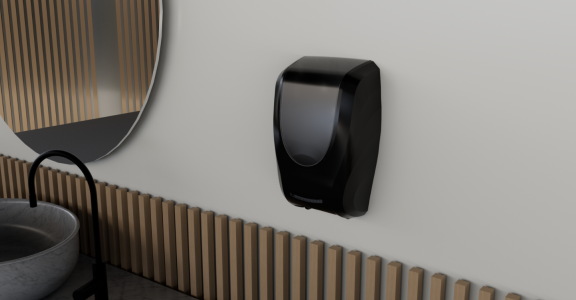

Ophardt Belgien – a specialist in hygiene products – investigated the possibility of optimising part of their soap dispenser production, to facilitate the process for operators. The intention was to introduce a cobot and vision system.

Demonstrator

In the Sirris and imec labs, the project partners developed a set-up whereby a cobot takes the holders from the rack. The cobot is equipped with proximity sensors to locate the holders. An additional challenge is that the holders sometimes stick to the rack due to the anodisation process. The cobot must be able to sense the amount of force required to separate the holder from the rack.

After removing them from the rack, the cobot places the holders on a conveyor belt to the quality control area. A second cobot picks up each one and holds it in front of a vision system (developed by Ghent University), which takes a photograph from each side. The photographs are analysed automatically. An operator then runs a final inspection on the holder, with on-screen access to the photographs and analysis.

Promising test results

The system to remove the holders from the rack was 100 percent successful, with automatic quality control accuracy on a separate batch of 97 percent. Operators’ working ergonomics were improved by adding a cobot to remove the holders from the rack. The consistency of quality inspections was increased by adding the vision system to support the operators’ work.

(Image by Ophardt)