How effective you can machine a part largely depends on the structural dynamics of all the components involved in the process. It can be seen as two systems: one concerning the machine tool, which includes the drives in the spindle, the tool holder and the cutting tool, while the other system concerns the workpiece being cut and the fixture set-up. Now to have an effective cutting process, the dynamics of both the systems should be taken into account.

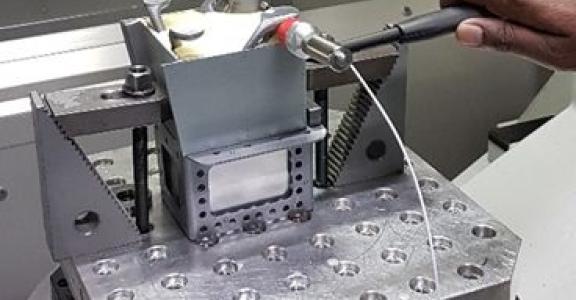

One way of understanding the dynamic behaviour of the system is by measuring the frequency response function (FRF). FRF is the variation of dynamic stiffness of a structure as a function of frequency (Hz). This could be done with something as simple as tap testing. In a tap test, the structure is exited with a small hammer and the response of the system is measured in terms of displacement or vibrations.

Determining the excitation frequencies of the system is very much necessary to be able to optimise a dynamic process. For example, in the case of milling the avoidance of chatter by determining the stability lobes helps in determining the maximum stable depth of cut as a function of spindle speed. Stability lobes are dependent on the particular workpiece material and cutting tool combination. These could be used further to optimise the cutting conditions to ensure maximum productivity and surface quality. This simple test is a more efficient way to optimise a process rather than extensive testing based on trial and error. Though the influence of the workpiece is minimal while using a solid block of material, it becomes very much essential while using a more complex workpiece-fixture combination which is usually the case while machining parts made by AM (additive manufacturing).

Benefits

Understanding machining dynamics can bring the following real benefits to your shop-floor:

- Improved productivity by increased material removal rate

- Machining of complex geometries and fixture set-ups

- Avoiding chatter free machined surface

- Reducing the time for post-processing, such as polishing, to enhance surface quality

- Prolonged tool life by reducing wear on tool and spindle

Sirris can help you to identify the bottle necks associated with the dynamics of the system thanks to our years of experience and knowledge gained through both academic and applied research with close industrial collaborations. Gain competitive edge by improving the performance of your machine tool, increasing your productivity and improve the quality of the parts being machined? Sirris is there to guide you through every step. Contact us for more information!