If a cobot can be used for palletising, then it can also be used for the reverse operation: depalletising. This reasoning is not entirely correct: depalletising with a cobot involves a lot of things that you need to take into account before you release the cobot on your pallets.

Today, depalletising is often done manually. It is a repetitive, sometimes ergonomic task with little added value that could be taken over by a cobot. However, depalletising is not simply the reverse of palletising. Practice has taught us that there are quite a few additional challenges involved in achieving good process reliability. We look at the challenges and different possibilities one by one.

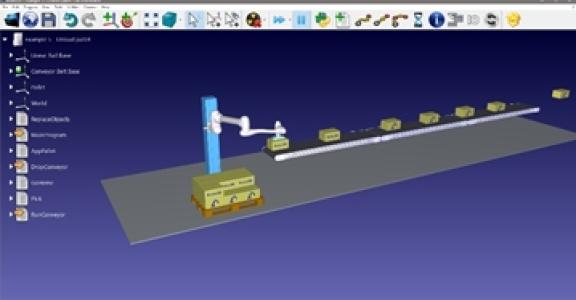

Simulation of the set-up

In order to have a first impression of what the set-up will look like, simulation is very useful. Estimating the cycle time is possible provided that the programming of the robot in the simulation environment is done realistically: make sure that no collisions can occur during the movements, that the process is well defined ... There are a number of different software packages on the market for this and most robot manufacturers offer their own software package. RoboDK is one of the brand-independent software packages on the market that Sirris sometimes uses.

One point of attention is that reality often turns out to be different from the simulation. For example, in the simulated operation in which the cobot removes goods from the pallet and places them on the conveyor belt, the goods are stacked perfectly straight on the pallet and land equally straight and at the same distance on the belt. In reality however, this is by no means always the case.

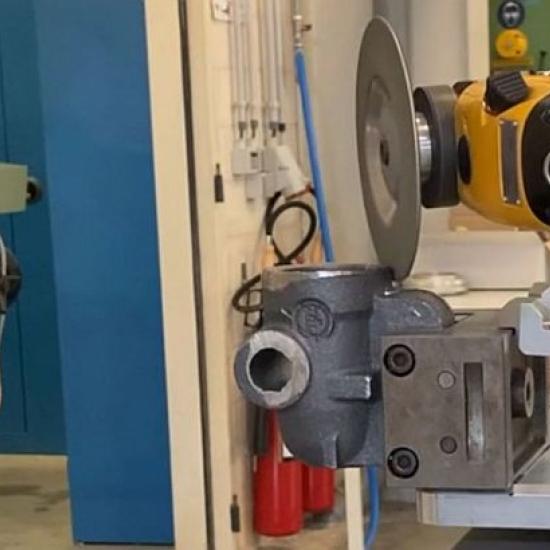

Picking up the goods

How are the products taken off the pallet by the cobot? Via a ‘toppick’ (along the top) or a ‘sidepick’ (along the sides)? If a side pick is desirable, for example if there is a lid or handle on top of the products, then the pushing force of the cobot must be accurately adjusted to prevent the other goods on the pallet from being pushed off the pallet when it is picked up. Providing a support wall at the back of the pallet can offer a solution here. In such setups, however, it is more difficult to programme the arm movement due to the higher risk of collision.

Single and multipiece picking

Can it be taken piece by piece or should the cobot be able to take several pieces at a time because of the cycle time? Are they the same or different goods? Here, you must determine to what extent it is possible to use the same gripper; after all, changing grippers can introduce errors. It’s also interesting if you have an idea in advance of the different types of packaging the cobot will have to handle. If this is not possible, a custom-made gripper can be used, equipped with a quick-change system to change the gripper for other product dimensions. If one universal gripper can be made to take all product types, then of course it will be preferred.

Other points of attention here:

- Is the payload of the cobot sufficient to pick up several pieces? Don’t forget to take the weight of the gripper into account.

- Are the products on the pallet in a structured pattern or randomly? Pallets are usually stacked by the supplier, warehouse worker, etc., which means that the position of the goods (start position) is not always predictable when the cobot arrives. You can resolve this by agreeing with the supplier, for example, that in future the goods will be stacked on the pallets in a certain way.

Stacked goods

Products may be stacked in straight layers on the pallet, but these layers can sometimes become slanted during transport in a truck or by handling with a pallet mover. This has consequences for depalletising with a cobot: fixed programmed gripper positions cannot be defined and the cobot has to search for the products. This can be based on the force sensitivity of the cobot (by deliberately provoking a collision with the products), by vacuum detection, when working with suction cups (with a predetermined vacuum level) or with the help of a camera system. However, the latter option creates additional complexity and is therefore preferably avoided.

Is there an intermediate sheet or cover between the different layers? In this case, the cobot must be able to recognise it and remove it.

What about the stack height? It is usually determined by the height of the loading space in the truck. Sometimes this height is too great for a cobot, so the top product on the pallet cannot be reached. In such a case, the cobot can be placed on a vertical linear axis.

Setting up the cobot

The dimensions of pallets may vary depending on the sector. Products may therefore be stacked on pallets of different sizes, a fact that should be taken into account when setting up the cobot. In addition, it is advisable to consider the following questions: how are the full pallets brought to the cobot? Manually with a pallet truck, via a roller conveyor or an AGV system? And how are the empty pallets removed? Manually or automatically, via a roller conveyor to a pallet stacker? Where and by whom will the wrapping film be removed from the pallets? If a large number of actions are required, the task is likely to be too complex for a cobot and is best left in the hands of the operator.

We often see that a cobot set-up is mobile, which is certainly interesting from the point of view of the accessibility of the line, but the set-up must also be able to be put back in exactly the same place after it’s been moved.

The drop-off points can also be a challenge: how many drop-off points are there, one or several? If there are several, does the cobot have sufficient reach? Think, for example, of a set-up of one cobot for two production lines, possibly with different products, that have to be dropped off at different locations. In such a situation, the stacking height and the position of the products per pallet must certainly be taken into account.

A risk assessment is required to ensure the safety of the set-up. Often cobots are set up in an open space, where operators may also be present. If the cobot has to work at a higher speed, zone monitoring is useful if the operators are (sporadically) close by. This can be done in various ways: by means of one or more laser scanners, light curtains or 3D camera.

A comprehensive and clearly structured overview of available cobots on the market can be found here.

This article was created within the context of our 'Operator support' testing ground, through which we demonstrate technologies and applications and stimulate companies through generic demonstrators that are available to the companies. This with the support of VLAIO in the context of Industry 4.0.