The ColRobFood project is aimed at flexible automation to strengthen the competitiveness of food companies. This is done through the development and validation of a number of proof-of-concept demonstrators, events and practical guidelines for the accelerated introduction of cobots in the food industry. The project ends at the end of November. An overview of what has been achieved in two years’ time.

The VIS project ColRobFood, a collaboration between Sirris and Flanders' FOOD, aims to accelerate the introduction of cobots (collaborative robots) in the food industry. The project was aimed at producing companies in the food sector as well as flexible automation integrators and technology providers. Some 25 participating companies participated, half of which came from the food sector. The user group met on a regular basis. These meetings usually took place at one of the companies and were attended by about 20-25 people, who provided the necessary inspiration, interaction and exchange of experiences and ideas.

In the course of the project, various events and workshops were also organised: during 'Meet the cobots' the participants were able to program their first cobot application hands-on. In 'Towards a safe human-cobot collaboration', in collaboration with Pilz and Stäubli who are both in the user group, the safety aspect was explained on the basis of the applicable standards and demonstrators.

Demonstrator-driven approach

In order to investigate and expand the possibilities with automation in the food industry, several demonstrators were set up. For example, at the request of one of the companies involved, Vandemoortele, a proof-of-concept could be implemented in production: it concerned a cobot for loading a filling line for margarine.

A second demonstrator was built that combines the advantages of an industrial robot with those of a cobot: this set-up, which included an industrial robot (IR) and a laser scanner, formed a small cell in which the robot carried out a pick-&-place order (of bags of coffee).

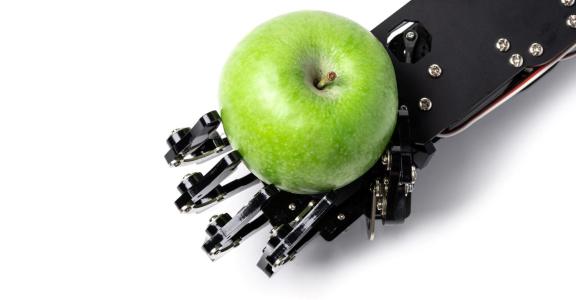

In addition, palletising via cobots was investigated, which turned out to be not always obvious in practice, certainly not for niche applications. Another possible application that was investigated was the manipulation of meat products.

It was important for the ColRobFood project to collaborate with other automation projects, such as ACROGRIP (KU Leuven) and the Interreg Cotemaco project: knowledge and experience were exchanged via the user groups. Within ACROGRIP a web tool for the selection of robotic grippers was developed.

Hygiene is an important aspect in the food industry and that is why there are many preconditions for automation in food companies, especially when there is direct contact with the food. Therefore, within the project, a white paper was compiled, 'Guide to hygienic design of robot-based automation systems', which can be downloaded here and published as a four-part blog series.

End of the project, not of the service

The ColRobFood closing event will take place online on 24 November.

The project may be finalised at the end of November 2020, but the project partners would like to further support the companies. As a food company, do you have questions about automation? Please contact us! Is your company located in West Flanders? In that case, you can get support within the framework of the Crisis Code Cracker.